Comparing product development stories across the continent

At a conference in Nairobi two years ago, an engineer visiting from Rotterdam stunned me with how easy it was for his team to order electronic components: an order for a BLE chip placed on Thursday evening would be fulfilled by lunch on Friday. Only a month before that, my colleague and I had spent two weeks waiting for a Bluetooth module for a prototype we were taking to the same conference. And two weeks was fast: we had a relationship with a Sparkfun reseller in Lagos, Nigeria. Most orders for electronic components took, at best, a month to arrive.

Long fulfillment times are the norm for small product manufacturers in Africa. Prior to this BLE project, we spent a month (with no tracking information whatsoever) waiting for a capacitor order from Aliexpress. Orders like this are an exercise of faith and at the mercy of the postal service who only offer home delivery for letters; online purchases must be picked up in person at a service office. For both hackers and small manufacturers in these parts, long wait times and uncertainty are an unavoidable part of the product development process.

This article introduces Africa, first as a continent comprised of different countries and markets, then as home to creative entrepreneurs manufacturing products for everyday use. Next, we examine the supply chain difficulties they face and end with recommendations for improvement.

African supply chain in context

Supply chain problems in Africa are quite complex, with most of them stemming from the sheer size of the continent. Africa’s land mass is greater than the USA, Europe, and China combined. Within this huge space there are 54 unique markets, few of which provide scale or adequate distribution infrastructure. Further complicating matters, there are over 2,000 languages spoken and very diverse cultural dynamics from one market to the next.

While supply is difficult, the demand is quite high. Nigeria’s construction industry, for example, imports about 70% of the raw materials and equipment needed to execute its contracts. As e-commerce, in the mold of Amazon, has seen rapid adoption across the continent and with the postal services in many countries being inefficient, e-commerce startups (like Jumia - Africa’s first unicorn startup - and Konga) have developed their own logistics outfits using motorcycles and trucks to deliver products to customers.

These issues affect manufacturing and product development in untold ways. I spoke with Soji, a supply chain expert at a leading consumer packaged goods company (he asked that his employer not be named) in West Africa, and he asserted that government policy has the largest impact on supply chain. Policy, according to him, affects product duty brackets, market size, and final logistic costs. In addition to country specific regulations there are also regional blocs that operate free trade zones or have special trade relationships. Similar to the rules guiding the common EU market, the Common Market for Eastern and Southern Africa (COMESA) and Economic Community of West African States (ECOWAS) are examples of these relationships on the continent. While these regions have established rules and duty exemptions, enforcement is often ad hoc.

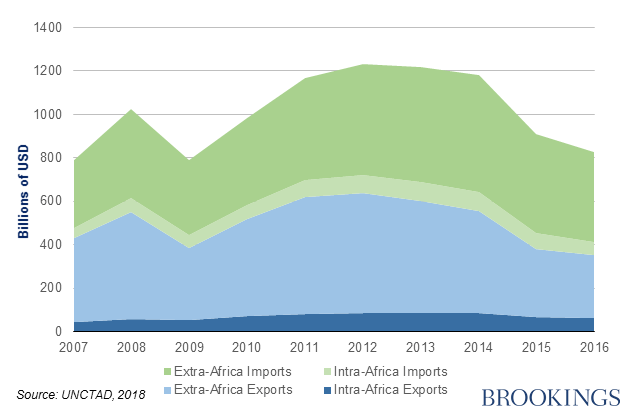

Soji tells me two stories about these two blocs. Within COMESA, where the shipping of goods across internal borders is supposed to be duty free, some countries in the region still charge a 25% duty - the same as he pays on goods from Tilbury, England. As a result, many manufacturers decide to ship their raw materials from outside of the continent because they can get superior quality for the same price. These duties explain why Africa’s extra-regional trade is far greater than intra-regional trade, as shown in the table below.

Meanwhile, the ECOWAS Trade Liberalisation Scheme only charges 7% in duties for intra-region shipping, although moving from one country to another means paying transit fees as forward clearing (a payment by which the good is cleared to transit through a country on its way to another). To explain, let’s take a look at Ghana and Nigeria, two countries on the West African Atlantic coast. Both Ghana and Nigeria are members of ECOWAS, and both are English-speaking. They’re also both large economies: Nigeria has the largest GDP of any country in Africa, and Ghana has the 11th largest. Lagos and Accra (the densest cities in Nigeria and Ghana respectively) are about 460 km apart and connected by a highway which sees a lot of trade.

Although they’re geographically close, the countries are separated by two other ECOWAS members - Togo and Benin, both of which are French-speaking. As a result, any trade done by truck would incur transit fees to both Togo and Benin and then an additional 7% duty in either Lagos or Accra.

To avoid that, some companies ship by sea. Both Lagos and Accra have large ports, and a direct vessel between the two will usually berth within 24 hours. But shipping companies often take up to a week to process and send bills of lading, delaying their goods’ progress through customs - and incurring daily rent on the vessels that carry them.

These barriers make it very difficult for smaller businesses — especially those working on new product development — to operate across borders in Africa. Multinationals, on the other hand, use two main strategies to reduce their costs. First, some large companies have been able to negotiate special treatment from the countries they operate in. Others with subsidiaries in each country of operation can ship goods from subsidiary to subsidiary, taking advantage of transfer pricing (the rules and methods that govern intracompany trades) to transfer goods and services to countries with better tax regimes than others, thereby increasing their profit and optimizing their inventory.

In different parts of the continent, entrepreneurs are managing their manufacturing process uniquely to reduce the impact of supply chain challenges on their business. While their products and business models are different, as are their scale and needs, each startup faces some of the same issues. To understand how they solve them and how these issues directly impact their business, I took a closer look at four companies across the continent.

Door-to-door shipping in Nigeria

Contract manufacturing may be associated with China, but Jude Abalaka is working hard to change that notion in Lagos, Nigeria. Tranos Contracting, a company he founded in 2010, manufactures a wide range of industrial products: steel enclosures for power generators, plastic enclosures for electrical devices, electrical panels, and diesel generators. They will begin manufacturing switches and sockets for consumer markets in the coming months.

Like any thriving business, Tranos is constantly looking to expand - in their case, into consumer goods. This expansion comes with its own supply chain headaches, which are indicative of the issues that plague African manufacturers. In an interview earlier this year, he lamented about having to order materials 3–6 months ahead of production to avoid clearing delays at the seaport.

“About 30% of our inventory is ordered from overseas and mostly shipped by sea, except [if] the item is light and urgent”, he wrote in an email. To manage this delay, Tranos keeps excess inventory on hand (tying up capital and making his business less nimble), though at times there are inevitable shortages that hold up production.

Apart from production roadblocks, even just procuring manufacturing equipment has its own logistical challenges.

Last year, as part of their expansion efforts, Tranos imported an injection molding machine. This took months to accomplish. After rounds of due diligence, they engaged a logistics company to do door-to-door shipping. FOB Logistics would pick up the machine in Bengaluru, India, manage the freight forwarding, clear customs, and pay duties as well as any inland logistics costs, before finally delivering it to Tranos in Lagos.

“By engaging with these [door-to-door] companies, we can trust that the goods will arrive in due time”, says Remi Akeusola, a supply chain manager at Tranos. Logistics firms deal with the port’s authorities regularly, importing multiple goods for different clients, and thus have a much smoother process clearing machines than startups. He goes on to describe the factors that necessitate using the services of a logistics company.

“It boils down to the cost, time frame of clearing and the response time in picking up the item from the manufacturers.” Engaging the services of logistics companies does not come cheap, as they charge a percentage of the total invoice value, a price that is probably too steep for some companies.

Delivery by proxy in Egypt

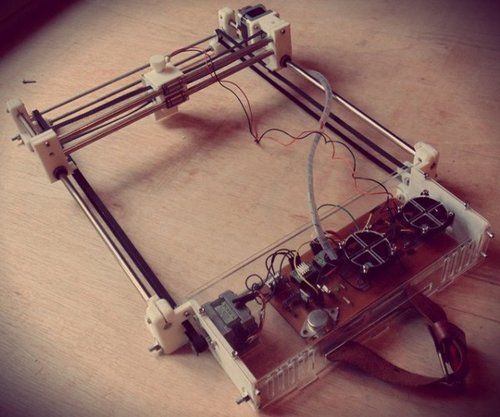

Risha, the word in Arabic for feather, symbolized the objective of Moushira Elamrawy and her Risha Laser team: To create a laser cutter that is light, open source, and portable -- like a feather. A Risha is also easy to use: a user would send a picture to the laser cutter to cut or engrave the image on light materials.

Built into the laser cutter’s design is its ease of assembly. The mechanical parts: 3D prints, threaded rods, and bolts were easily found in the spare parts markets in Alexandria; the electronic components were sourced from sound and lighting technicians — their main business being setting up elaborate Egyptian weddings — and university engineering departments. The last component, a 700mW laser diode, was purchased off Amazon.

However, Amazon did not ship the laser diode to Egypt. Moushira would ship batches of the part to a friend or colleague coming back to Egypt from the US or Europe, who would check the package in as their luggage, to avoid questions at customs.

“[Border] Security would ask you ‘Why are you bringing this into the country? What are you using it for?’”, she tells me.

Times are better now, she says. As part of her belongings, she counts 10 Arduinos bought from online electronics stores like Future Electronics and RAM Electronics - purchases that would have been impossible before the 2011 revolution. Although electronics have always been sold in stores, buying parts like ATmega and other microcontrollers is easier now.

Risha is currently on a hiatus, but Moushira is busy. When she is not working with an educational institution to open a makerspace, she is advising the government on new policies to support engineering product development to promote technology export.

Inventory forecasting in South Africa

Cape Town is a beautiful port city on South Africa’s southwest coast. It is a popular tourist attraction for its weather, fauna, and Robben Island - where Nelson Mandela was imprisoned for 18 years. The legacy of apartheid is chiefly responsible for South Africa being the most unequal country in the world, according to the World Bank. Due to this, the chronically poor live in shanty-towns and slums like Khayelitsha in the center of the city.

In 2013, a huge fire broke out in this slum claiming five lives, razing 800 shacks, and displacing 4,000 people. In response, a group at the University of Cape Town developed Lumkani — a heat detector built on a mesh network with a backend system the team calls ‘Watch Tower’. The devices are portable and easy for homeowners to install themselves. When a Lumkani device detects a fire, it raises an alarm over text message with the GPS coordinates of the detecting device.

Initially set up as a social enterprise, Lumkani was launched as an Indiegogo campaign in 2015 and has since used grant funding to build a manufacturing business. In addition, they have rolled out an insurance product where homes with the devices are underwritten by Hollard Group to a value of about 40,000 Rand (about 2,650 USD); they also have plans to expand to other home detection products. Just three months ago, they closed a seed funding round.

Their supply chain has evolved since 2015, with more parts coming from overseas now. “90% of the components are manufactured or sourced out of China and we use local distributors to deliver the parts” says Craig Burden, Lumkani’s Lead Engineer.

After the components arrive in Cape Town, Lumkani hands them off to a local manufacturing outfit who populates the PCBAs, performs product assembly, and packages the devices. With this set up, their weekly production capacity is 2,000 units.

The signature light blue plastic casing that covers the product is manufactured in China as it costs less than manufacturing locally — even with the duties and freight charges. In addition to cost, their Chinese contract manufacturer provides better service than their previous, local, manufacturer.

Remote manufacturing partners aren’t without their costs, however. “Because it takes about a month to a month and half to arrive by sea, we order on average 25,000 cases not less than two months in advance of when we want them here” Craig included.

Even more challenging are component orders. Thanks to the recent worldwide capacitor shortage - which has affected businesses in Africa as anywhere else - Lumkani’s capacitor orders take about 22–35 weeks to arrive. Even though they engage the services of registered South African distributors, the delivery times vary by component and season.

“We’ve had to develop some tricks” he says. One trick is to order components from lesser known manufacturers; the other is to engage with trusted buying houses, essentially stock keepers who provide no guarantees, source the components from any supplier, and have no return policy. “These stock keepers could even be people buying components at the market in Shenzhen, but we have to trust them because for a lot of our components we can’t get them from anywhere else.” Whatever it takes to get the job done.

Cross border shipping from Kenya

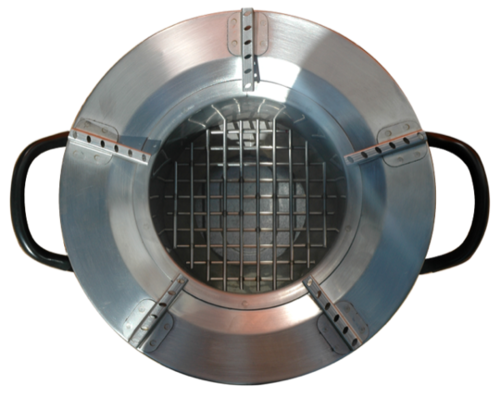

Cooking stoves in many parts of the world run on coal, wood, and other polluting fuels. For a while now, there has been a worldwide drive to make these stoves run cleaner: using less fuel and producing less smoke and emissions.

In Kenya, this drive is one of the reasons behind BURN Stoves, a stove manufacturer in Nairobi. They have three product offerings with prices ranging from $38.90 to $52.50, all made completely in house. The stoves are sold through micro-finance institutions and retail in supermarkets in Kenya and a few neighboring countries.

BURN’s stoves have ceramic insulation, a stainless steel grate and an ashtray. While their products have no electronic components, they source many of their raw materials from China, including stainless steel and ceramic fibre. Other parts such as packaging and boxes are sourced locally in Nairobi. Before 2014, some of the manufacturing was done in China; they’ve since moved home in order to empower local industry and benefit from cheaper labor and grant funding. At their factory in Ruiru, they powder coat, assemble, and package their stoves. The company projects an output of 3.5 million stoves in the first decade of the factory’s operation.

Moving manufacturing to Ruiru has impacted their logistics, and, in turn, their lead times, with local government policy now playing a tremendous role. For example, the ports they use — in Mombasa and Nairobi — are currently undergoing structural changes, causing clearing to take significantly longer.

“The best we’ve ever done was about 10 days, that was amazing! Now, the average is about 3-4 weeks passing through customs and the KRA [Kenya Revenue Authority],” Mohammed Ali, who manages their logistics, told me. To manage this, their part orders are made four months in advance, using the sales team’s volume predictions. However, a lot can change in four months: policy, weather effects, and even taxes. In their usual orders they add a four week buffer for imported materials — one week for locally sourced parts — but from time to time they run out of stock, causing them to either halt the production line or only make partial stoves.

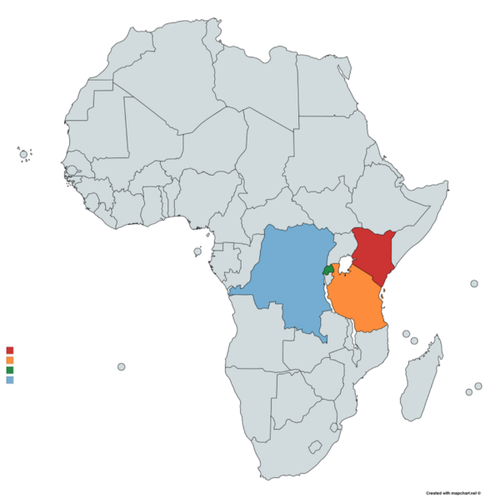

Distribution presents another set of challenges, as they have had to build their own delivery network. Within Kenya, the company has its own logistics infrastructure - using trucks to move the stoves across the country; on occasion it engages Wells Fargo, a logistics company (not the American bank). BURN also sells its stoves in Tanzania (shown on the map in orange), Rwanda (green) and the Democratic Republic of Congo (blue). To get their finished stoves to these countries, they ship by air, land, and sea freight.

At up to $4 per kg, air is extremely expensive. The stoves each weigh roughly 5kg and would cost about $20 each to fly: more than half the price of some of their stoves.

Shipping by land is often the most cost effective option, but proves difficult in the Democratic Republic of the Congo (DRC) due to its dense forest regions and unpredictable politics. So far, they have succeeded by employing the services of middle men or shipping by boat.

“We have had to ship to Congo many times by sea around the Southern coast of Africa” says Mohammed, a voyage that could last up to 3 weeks. In rare occasions they have tried shipping by small boats, but these offer no insurance and are highly unpredictable. These distribution challenges impact how fast BURN can deliver to their customers in foreign markets and limits their plans for expansion; a supply chain is only as strong as its certainties.

The way forward

These four companies are very different. Risha was founded and run on a small scale out of a makerspace; Lumkani has used a combination of crowdfunding and grants; Tranos serves local businesses as a contract manufacturer; BURN ships overseas at a large volume. Each faces similar supply chain challenges, and has made sacrifices in an effort to produce exportable technology and grow a sustainable business.

For these companies, reducing their supply chain woes would greatly improve their operations. With an improved clearing process and more efficient ports, BURN would be able to predict their sales closer to the time of sale and maintain a smaller inventory. With a more informed customs force, Risha can source diodes to produce laser cutters on a schedule. Tranos would get their new products to market faster and ship their tools faster enabled by smoother freight forwarding. While with enough stock on their hands, Lumkani would deliver bulk orders more confidently.

For makers developing new product concepts, improving their access to components will reduce their development time. But the actions required to achieve these objectives are not clear cut.

An EY report from 2014 (PDF) prescribes a number of opportunities worth exploring. Chief among them is to improve the shipping network, integrating road and sea freight, especially within regional entities. None of the startups I interviewed for this article sourced materials from other countries within the continent. Instead, when they couldn’t find in their locale, they went outside the continent. Improving the road networks within countries, along with more open borders, will accelerate the movement of goods within Africa.

That said, most materials will continue to be shipped from outside markets - especially from Asia. To improve lead times, more distributors (with consistent stock of commonly used parts) need to be present across the different regions of Africa. While it seems intuitive that where there is demand there should be supply, the lack of distributors is due to the fact that many hardware developers work in silos, often with no informal network. Without such networks, would-be distributors have no insight about the local demand. In addition, the high exchange rates of local currencies to the dollar affects the ability of entrepreneurs to order parts they need.

For companies like Risha and Lumkani it’s possible that makerspaces could act as a distributor, providing tools and components for product developers to work with. Some of these already exist in Kenya and Ghana. Gearbox (Kenya) provides industrial tools and training for hardware entrepreneurship in a flexible working space, as does Kumasi Hive (Ghana). These spaces regularly order parts from overseas so that their members always have the tools to work.

Bigger companies, like BURN, could work with the fledgling e-commerce startups by offering their products to be sold and distributed on these platforms. With these platforms they could forecast their sales better and even outsource delivery, saving the cost that they bear and reducing the uncertainty of shipping. Better forecasts inform slimmer inventory, bringing their manufacturing to a just-in-time process.

The biggest opportunity lies with policy. Simplifying duties and clearing procedures at the ports would greatly improve the supply chain, and pairing these with a technology development policy would be a double win. Some of the options of such policy could be:

- Relax duties and import tariffs on electronic components, especially when an industry that uses such components is budding. Unfortunately, current trends don’t point in this direction: eight months ago, the Nigerian government increased the tariffs on solar panels by 100%. Such moves hamper the development on renewable technology products — a growing industry in the country.

- Allow tax relief for a number of years to companies beginning technology export. This will create an incentive for entrepreneurs to develop products for export, especially in countries that have cheap access to raw materials.

- Open regional trade areas and enforce the rules. The continent is big enough to trade within itself, but the gatekeepers need to keep the gates open for the markets to dictate the price and direction. The Continental Free Trade Area (CFTA) agreement aims to achieve this, but member nations have been known to undermine such agreements in the past.

These steps require a refocus with governments looking to the future instead. The continent produces 11 million youths who join the workforce every year. As such, governments look for Foreign Direct Investment from multinationals in the FMCG and construction industries who can provide this.

This model is not sustainable as the jobs created are not highly skilled and labour costs could always increase; essentially, governments are focusing on easy solutions and ignoring the long term benefits that other options might offer. By formulating policies around technology export and providing an enabling environment for product development, these hardware startups will eventually create jobs, improve the talent pipeline, and grow the countries’ GDP.