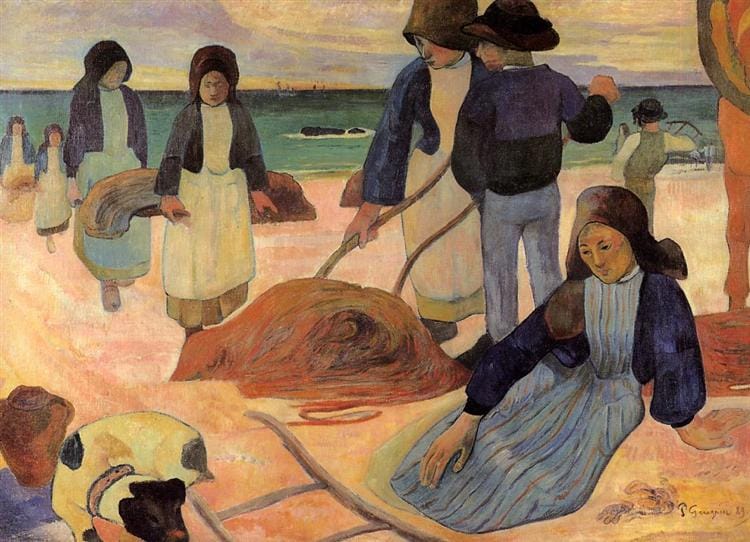

For a brief time in the late eighteenth and early nineteenth centuries, the West Coast and Isles of Scotland were home to a kelp industry that grew with the industrial revolution, drawing landowners, chiefs, and laborers into a boom that lasted just a handful of generations—and then collapsed. Today, the word kelp is used to describe a range of large brown, red, and yellow seaweeds. But in that time, in an industrial context, kelp meant the finished product: processed alkali in the form of large glassy slabs, made from seaweed that was dried, burned, and washed, to be shipped to Liverpool for use in glass- and soap-making. A description of workers from 1831 describes the life that kelping entailed:

If one figures to himself a man, and one or more of his children, engaging from morning to night in cutting, drying, and otherwise preparing the seaweeds, at a distance of many miles from his home, or in a remote island; often for hours together wet to his knees and elbows; living upon oatmeal and water with occasionally fish, limpets and crabs; sleeping on the damp floor of a wretched hut; and with no other fuel than twigs or heath; he will perceive that this manufacture is none of the most agreeable.

The end of the Napoleonic Wars, changes in import and tax regimes, and a new competitor–the Leblanc process, which TW wrote about here last month–brought down Scotland’s kelp industry. But the demand for the finished product of kelp cultivation and incineration, which today is referred to as soda ash, continued to grow.

Soda ash, or sodium carbonate, Na2CO3, remains an essential ingredient of soap. It’s also used in steel production and metal refining to control acidity and eliminate impurities; it’s used in slips and glazes for ceramics and glass; and increasingly, it’s used as an intermediary during lithium battery production. Sixty-five million metric tons of soda ash were produced in 2023, a little more than seven kilograms per person on Earth. It is safe to assume that none of it was derived from seaweed. Instead it is either mined or, more likely, synthesized from salt brine and limestone through the Solvay process.

The Solvay process was developed by Ernest Solvay, a Belgian industrial chemist, in the mid-nineteenth century. He built a seventy-nine-foot gas absorption tower, and in it bubbled carbon dioxide through a descending flow of ammoniated brine, precipitating sodium carbonate as a result. Based partly on the success of this process he founded an eponymous company, Solvay, which today describes his innovation on its website as “radically new” and a “technological breakthrough.” Then as now, part of the Solvay process’ appeal was that its inputs, salt brine and limestone, were inexpensive and readily available. Its principal byproduct, calcium chloride, was preferable to the pollutants resulting from the Leblanc process: hydrochloric acid, which killed fish and sickened people when released into the environment, and the vast sulfurous piles of black ash called galligu, deposits of which, left over from the nineteenth-century heyday of the Leblanc process, still cause trouble for civil engineers.

But Solvay’s first patent application was denied, partly because not everything he had done was radically new. While his process was a technological breakthrough, the basic chemical reaction at its heart had in fact been known since 1811. Solvay filed a second patent based on the apparatus and procedure rather than the chemistry, and that one was successful. Nevertheless, Solvay thought of himself as a pure scientist at heart, and an industrialist by circumstance. He became enormously wealthy. The process he devised delivered an economical and practical method for industrial production of soda ash–something long sought-after, and widely useful. And yet, the fundamentals of it had been sitting there for a while, discovered decades earlier by a young Augustin-Jean Fresnel.

This isn’t uncommon. Historian Desmond Reilly described the evolution of the Solvay process as “an interesting example of the way in which a discovery can be made and then laid aside and not applied for a considerable time after.” The use of statistical inference in Arab cryptology is another beloved example of this occurrence, with a far longer lapse between the early innovation and its later resurgence: The cryptologist Al-Kindi, born in 801 and raised in Baghdad, used the relative frequencies of letters to decode encrypted messages centuries before Pascal and Fermat’s correspondence kickstarted modern concepts of probability. Mendelian inheritance, too, was proposed and then forgotten for decades before resurfacing like a classic recessive gene.

A 2004 bibliometrics study gave a name to ideas in science that languish in obscurity before eventually gaining recognition. It called them sleeping beauties, and measured the length and depth of their sleep (how long they went unnoticed, and how unnoticed they actually were) and the intensity of their awakening (the number of citations in the period following their rediscovery). I’m thinking now about the sleeping beauties in my own life: lessons I learned and forgot, things I knew once and might come to know and celebrate again. I’m seven months pregnant, and anticipate that having a child will return me to some of the questions I had when I was very young, and that life’s new demands will require me to draw on everything I have available. So much experience in the next few months and years will be utterly new to me. But I’m also curious about what I might unearth or rediscover, what knowledge or feeling might come back in a newly accessible form, transformed by the passing of time or the changing of circumstances into something I can really use.

Soda ash is a critical component of modern glass production, and has been used in glassblowing for thousands of years. Historical accounts, mythic as well as archaeological, trace the invention of glassblowing to the area around the river Belus, where pure, white sands are rich in the raw components for glass production: silica and natron, a natural mineral source of soda ash. The first century historian Josephus wrote of a place outside the city of Acre where common sand could be transformed to glass:

the place is round, and hollow, and affords such sand as glass is made of, which place, when it hath been emptied by the many ships there loaded, it is filled again by the winds, which bring into it, as it were on purpose, that sand which lay remote, and was no more than bare common sand, while this mine presently turns it into glassy sand. And what is to me still more wonderful, that glassy sand which is superfluous, and is once removed out of the place, becomes bare common sand again.

The archaeological traces of glass production in historic Palestine document the link between abundant natron and early innovation in glassmaking. For most of the first millennium, almost all the glass that made its way throughout Europe and the Mediterranean came from Egypt and Palestine. Much of the physical heritage has been lost, excavated (historian Abdel Yahya called Palestine “probably the most intensively excavated land in the world”) and destroyed or removed from the Levant. Architect and artist Dima Srouji evokes the Belus in her installation The Red River, and the displacement of glass archaeological artifacts from the Levant in Ghosts. Each vessel in Ghosts is a replica of an artifact currently held in a western institution, “drawn, rendered, and then reproduced, as a ghost of the original, by expert glassblowers in Jaba’ Palestine.”

Around the eighth century, glassmakers in the Levant transitioned away from natron as a source of soda ash, replacing it with plant ash. Like kelp, some salt-tolerant land plants can be processed to yield an impure sodium carbonate solution, which can then be refined to soda ash. The plants used for this are named saltworts and glassworts, and they are examples of halophytes–plants that thrive in brackish wetlands and saline soils. As Lily Saporta Taigiuri notes in “Food Forecast: Salt,” these kinds of environments are becoming more common with rising sea levels, groundwater contamination, and the release of salt and briny discharge from agricultural and industrial activities. Because they fare well in difficult circumstances, edible halophytes are sometimes associated with times of deprivation. Taigiuri quotes chef Lorenzo Barbasetti di Prun: “these plants are good for Michelin star restaurants and wartime.” If you scroll to the end of Taigiuri’s essay, you’ll find a recipe for preparing caper leaves and sea fennel.

Making soda ash from kelp or saltworts is labor intensive; making soda ash through the Solvay process is energy intensive. It’s generally cheaper and less polluting to mine soda ash than it is to synthesize it. The world’s largest deposit of soda ash is in Wyoming. It contains perhaps a hundred and twenty-seven billion tons of trona, another naturally occurring form of sodium carbonate whose name (like natron) comes from the Ancient Egyptian ntry. If you’re in the US and you have baking soda in your cupboard, it likely came from the Green River Basin, which extends from southwestern Wyoming into corners of Utah and Colorado and which is home to, among other things, a large Arm & Hammer factory.

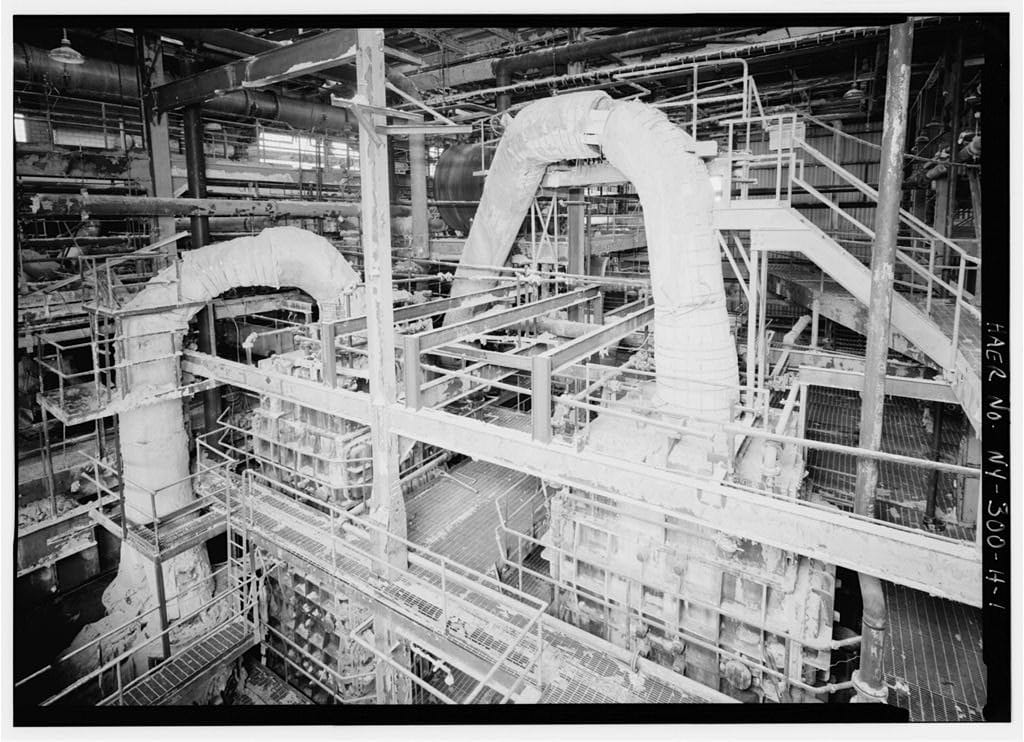

The video on this page offers a glimpse into one mine, with its vast machinery and ore gliding by on a conveyor belt to the crusher. Wyoming Mining says that “an underground trona mine is like an underground city,” complete with maintenance shops, parts warehouses, lunch tables, bathrooms, and streets. The world is full of these smaller interior worlds, in which people’s whole working lives can be spent.

“There’s more roadways in here than there is in the whole city area of San Francisco,” a health and safety officer from a different mine told Cowboy State Daily. His mine’s bathrooms incinerate human waste, and its ventilation system circulates a constant breeze of fresh air through the vast tunnel network, keeping dust down and mitigating the buildup of methane. Salty, waterlogged icicles form on the ceilings, so fragile they melt immediately when brought to the surface. Thinking again of sleeping beauties, I wonder which lessons or memories from my past will stand up to exhumation. Not everything survives being brought to the surface.

Thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible.

Love, Natasha

p.s. - How to treat a stain with sodium percarbonate: make a paste of warm water and a spoonful of the sodium percarbonate, and rub it into the stain with a toothbrush. Depending how deep the stain goes, you could apply it to both sides of the fabric. Let it sit a while, then wash it out. This is magical and works for almost everything.

p.p.s. - We care about inclusivity. Here’s what we’re doing about it.