If you walked into my workshop, opened the flammables cabinet, and asked me how some bottle of solvent or thinner was made, there’s a decent chance my reply would include the phrase “cooked up in a lab.” The same could be said, I suppose, of anything that someone might refer to in conversation as a “chemical.” How is ammonia made? It’s cooked up in a lab. Epoxy resin? Cooked up in a lab. Dishwasher rinse agent? Cooked up in a lab.

It’s as if my passing awareness of chemistry allows me to conceive of all materials as having resulted from obscure chemical processes, the input to which are a few squirts of fungible goop. I might imagine labs full of primordial liquids, which are heated, stirred, and distilled to make whatever substance a consumer products company decided to sell me – as if the important thing about dish soap isn’t the fact it’s made from (among other things) palm oil, but that it was made by chemists. But this can’t be true: the chemistry matters, of course, but so does the palm oil. Turn from the sink to the dining room table, then, and consider where my dinner comes from. Maybe tonight it was cooked up in a commercial kitchen a couple kilometers from my house, but the fact remains that its ingredients came from somewhere – from a produce market in the Bronx; from farmers in New Jersey and Idaho; from dirt and sunlight, ultimately.

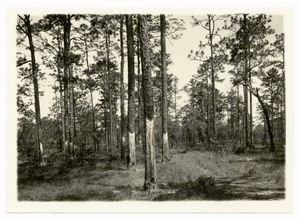

The same is the case with many of the solvents in my flammables cabinet. Turpentine, for instance, is distilled from the resin extracted from pine trees. Much like natural latex, turpentine resin used to be tapped from living trees, though these days it is also produced as a byproduct in pulp mills. Once distilled, turpentine will thin oil paint, dissolve unvulcanized rubber, and if you work with it enough, cause loss of vision, headaches, and a range of other unpleasant and eventually lethal effects.

Charles Goodyear would have been keenly aware that he was using plant-based materials as he worked towards vulcanization in the 1830s. The inventor used turpentine extensively, and though the solvent was critical to his experiments, he also seems to have hated it. Turpentine had been in use by rubber entrepreneurs since at least 1763, when multiple teams of French scientists independently documented its effectiveness as a rubber solvent. Before that time, rubber had to be made into finished goods pretty close to the actual rubber trees; otherwise the liquid latex would spoil on its way from Brazil to Europe and the US. But shipping finished products across the ocean caused its own issues: These boots, trinkets, and erasers were unvulcanized, and hence were susceptible to all the degradation and failure I described previously, and by the time they got into the hands of European and American consumers, they were probably looking a bit worse for the wear. So instead of importing finished goods, nineteenth-century European and American buyers came to prefer rubber in its commoditized form: Fine hard para balls. These would then either be cut into finished goods, or chopped finely, dissolved in turpentine, and then reformed into a final shape.

Goodyear disliked turpentine for two reasons: its cost (Charles Slack notes that a gallon cost around seventy cents, or roughly $23 today – “a huge expense for a material whose ultimate function was to disappear into the atmosphere”), and its tendency to evaporate inconsistently and incompletely. But Goodyear was, as it happened, living at a critical time in human technological development. His work on vulcanization started in 1834, roughly thirty-seven years after coal gas opened the floodgates to a panoply of fossil fuel derivatives. And it was this shift – when humans started cooking up valuable stuff from primordial goop – that led to the first successful rubber company.

Read the full story

The rest of this post is for SOW Subscribers (free or paid) only. Sign up now to read the full story and get access to all subscriber-only posts.

Sign up now