How the Brazilian rubber tree made Manaus – and then left it behind.

Editor’s note: This is the fifth post in our series on the history of rubber. Parts one and two are free for everyone to read, and the paywall on part three has been disabled for this week only. Supporters and Members of Scope of Work can read part four here.

In the second half of the nineteenth century, Manaus was a boom town. Manaus is the capital of Amazonas, a province more than double the size of Texas, and in 1872 the city accounted for roughly half of that province’s population. And Manaus’ economy – and the economy both up and down the Amazon from Manaus – was dominated by the rubber trade.

Basically every history of the Amazon includes the same anecdotes about the period. They mention the opulent Teatro Amazonas opera house, and something about rubber barons lighting cigars with 500-milreis bills, and a vague anecdote about someone “watering his horses with buckets of champagne.” City officials were flashy and frivolous: The gubernatorial palace was halfway built, then dynamited and rebuilt. A few years after the Teatro Amazonas opened, the mayor boasted that he would soon have it demolished and replaced with something even grander.

All of which is to say that economic development wasn’t exactly the first priority in Manaus during the boom years. Those in power invested their rubber profits into things that raised their own profiles and standards of living; they cared more about grandeur than they did about long-term productivity. Manaus is located in a region teeming with natural resources, but instead of setting up local supply chains – for staple foods, for building materials, for specialty goods – they relied almost exclusively on expensive imports. And they exported basically one agricultural commodity: raw unvulcanized rubber. Little attention was paid to adding value to that commodity, or improving transportation systems, or (god forbid) simply growing food for rubber workers locally.

For all the horrible aspects of the Amazonian rubber industry, it nonetheless presented the region a huge economic opportunity. The world desperately wanted rubber, and as I described previously, the Amazon basin was really the only place that could produce it. This is because while latex is produced by roughly 10% of the plants on earth, the only plant that makes it efficiently enough for human usage is the Brazilian rubber tree, Hevea brasiliensis, which the Amazon had a natural monopoly on. Hevea grows wild in the Amazon basin. All a Brazilian entrepreneur had to do was harvest the latex, float it down the river, and sell it on the export market.

The question is, what to do with the rubber profits? In Rubber Manufacturing in Malaysia, a short academic book that in many ways explains the collapse of the Brazilian rubber industry, C.C. Goldthorpe argues that agricultural exporters should invest in a manufacturing base that can add value to their primary crops:

At the early stages of development, tropical countries grow agricultural crops adapted to the local climatic and ecological environment…Primary crop producers, at a later stage, have the opportunity to move up the ladder of comparative advantage by developing a secondary manufacturing industrial base that utilizes the crop as raw material. Transforming the agricultural commodity into manufactured products that are sold into export markets adds value to the commodity and increases foreign exchange revenues that may be used to finance national development projects.

Brazilian producers did not take up the opportunity to move up the ladder. Which is fair enough, I suppose – dynamiting and rebuilding palaces is tough work – but in retrospect they were facing an inevitable collapse, and they needed only to look to the Andes for a glimpse at what would happen to hevea.

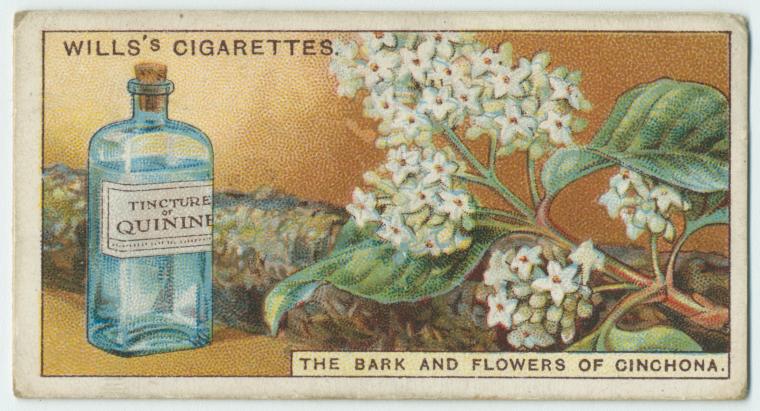

As I described in my recent post on naphtha, coal tar, and the Mackintosh, plants played a critical role in the technological development of the early twentieth century. Longleaf pine orchards supplied the turpentine that was used extensively in the development of early rubber products; cinchona supplied the quinine that in no small part allowed Europeans to explore and exploit the tropics; hevea enabled the bicycle, the automobile, and much of modern industrial machinery to flourish. If someone was in the business of building an empire in the 1870s, access to plants like longleaf pine, cinchona, and hevea would be matters of national security.

A good example of that someone might be Joseph Dalton Hooker, the Director of the Royal Botanical Gardens at Kew. A botanist and explorer who was Charles Darwin’s closest friend (and “the first recognised man of science to publicly back” the theory of evolution), Hooker recognized the significance of both cinchona and hevea, and in collaboration with the British India Office he arranged to have both plants smuggled out of their native environments. Cinchona went first, and for good reason: It was the source of the only known malaria treatment at the time, and as such was an incredibly valuable tool for empire-building. As the surgeon general of the British Army said in 1897:

to England, with her numerous and extensive Colonial possessions, it [cinchona bark] is simply priceless; and it is not too much to say, that if portions of her tropical empire are upheld by the bayonet, the arm that wields the weapon would be nerveless but for Cinchona bark and its active principles.

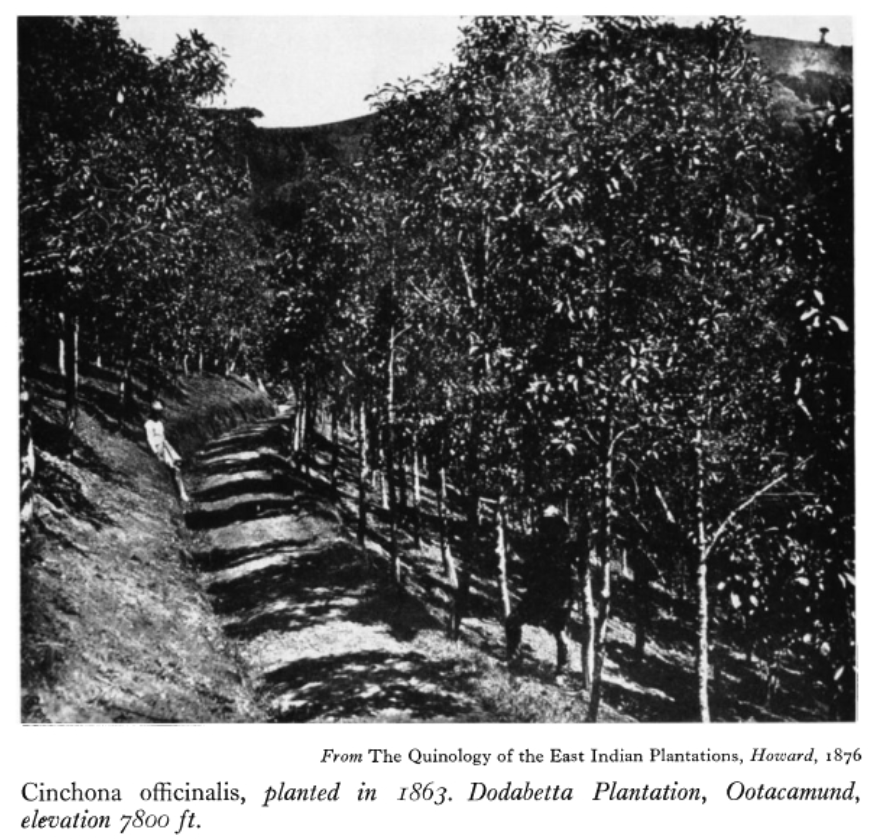

Cinchona was stolen from South America at least three times (once each from Peru, Bolivia, and Ecuador) by representatives of Kew Gardens. I imagine Hooker must have planned the thefts the way that we might plan to steal source code or engineering documents, and descriptions of these three missions are subversive and rollicking, in a nineteenth-century colonial sort of way. Clements Markham, who was eventually knighted for his efforts, apparently took up coca leaves while in Peru and was chased out of the country by “jealous” local authorities. In the end over a hundred thousand cinchona seeds were smuggled out of South America, and Hooker eventually cultivated at least ten thousand seedlings in a heated greenhouse at Kew. Over the next half-century, Andean cinchona output would be reduced to nothing, out-competed by plantations in South Asia and Indonesia.

The same story was repeated at a grander scale with hevea, spurred largely by the same Clements Markham, who appears to have wanted to pull off one last job. Again, the heist took multiple attempts to complete, but in 1876 a botanist named Henry Wickham sent about 70,000 seeds from Para, Brazil to Kew Gardens. They were planted the day after their arrival, and about 3.75% of them germinated. Within a year, living hevea seedlings had arrived in Singapore, and by 1890 unvulcanized rubber had been produced there.

Like its Amazonian forebear, the rubber industry that developed in Singapore, Indonesia and the Malay Peninsula was brutal to its labor force. But it was also much more productive, quickly eclipsing Amazonian output, and this is at least partly due to the way that the two labor forces were organized. In essence, the seringueiros (rubber tappers) in the Amazon were hunter-gatherers – whereas in Southeast Asia, rubber was produced by industrial agriculture.

The Southeast Asian rubber industry also owes much of its success to luck. Other agricultural commodities that had been popular in the region – tobacco, sugar, coffee and tea – experienced difficulties in the late nineteenth century, leaving farmers looking for alternatives. Indonesian tobacco production had declined during the 1890s depression; sugarcane producers in the Malay peninsula were struggling to control rat populations; coffee leaf rust swept through Indonesia in the 1880s; Sri Lankan tea plantations faced leaf blight around the same time. By the mid-1890s, Southeast Asian farmers were interplanting hevea with manioc, tea, sugar, and coffee, and after the turn of the twentieth century full-scale rubber plantations began to arise.

But the organization of labor is what really distinguishes the Amazonian rubber trade from the one that emerged under British and Dutch colonial rule in Southeast Asia. To be clear, both systems were deeply immoral and brutal. But in the Amazon, seringueiros were isolated from the business of rubber trade. They were sold imported machetes and tinned food, sent up the river, and forced to live alone in inhospitable jungles for months on end. In contrast, rubber plantations in Southeast Asia were coordinated colonial affairs, which encouraged the development of supporting industries and – in spite of their cruelty, racism, and exploitation – conferred at least some technological skills to the people who were forced to labor in them. And people labored in staggering numbers: In 1927 alone, 120,000 Indian laborers were brought to Malaya to work rubber. As C.C. Goldthorpe wrote about rubber plantations in what would become Malaysia:

Natural rubber production provided a source of raw material for the development of forward linkage activities through the establishment of downstream rubber goods industries…From their establishment, rubber plantation and tin mining companies operated as industrial concerns that required capital, managerial expertise, wage labor, specialization of production and a degree of technical knowledge…the labourers working on plantations constituted a disciplined, wage earning, rural proletariat well suited to the demands of an expanding, industrial production sector.

Nothing of this sort existed in Manaus at the time. The labor force was almost intentionally disorganized; the only bank in town was British; there was no real effort to create homegrown innovations in rubber technology. In Southeast Asia, the rubber industry was just that – an industry. Rubber farmers were regimented and diverse in size, with both smallholders and multinationals playing significant roles. The Colonial outposts of the Royal Gardens developed new latex harvesting and processing techniques, resulting in higher outputs and a more consistent finished product. And over time, Malaysia developed not only the skills to produce latex in staggering quantities, but also an industrial base capable of manufacturing finished rubber products, synthetic rubbers, and a wide range of rubber manufacturing equipment. Whereas in Manaus, the rubber industry is virtually nonexistent today.

I’ll be back soon with more on the rubber industry; thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible. Among other sources, the following texts were extremely helpful in writing this post:

- Rubber Manufacturing in Malaysia: Resource-based Industrialization in Practice. C.C. Goldthorpe, 2015.

- Manaus: Social Life and work in Brazil’s Free Trade Zone. Leo A Despres, 1991.

- North Brazil: Physical Features, Natural Resources, Means of Communication, Manufactures and Industrial Development. EC Buley, 1914.

- Rubber: A Story of Glory and Greed. Howard and Ralph Wolf, 1936.

- From Silver to Cocaine: Latin American Commodity Chains and the Building of the World Economy, 1500-2000. Zephyr Frank, Aldo Musacchio et al, 2006.

- History of the Rubber Industry, Compiled under the auspices of the Institution of the Rubber Industry. P. Schidrowitz & T.R. Dawson, editors, 1952.

- Brazil and the Struggle for Rubber: A study in environmental history. Warren Dean, 1987.

- Science and Colonial Expansion: The Role of the British Royal Botanic Gardens. Lucile H. Brockway, 1979.

Love, Spencer

p.s. - We care about inclusivity. Here’s what we’re doing about it.