Images from the 2014 construction of Maggie Daley Park in Chicago are something to behold. Where one might expect earthmoving equipment and rough piles of dirt, there was instead a sea of white oversized foam bricks, scattered and stacked beside rebar and retaining walls like the landscape architects had decided to build a park from gigantic Lego bricks. This is geofoam. The expanded polystyrene blocks now sit below the surface of a verdant landscape, giving shape to the contours of the 20 acre park.

Engineers are often called on to make the near-impossible happen. An underground tunnel joining England and France? Ok! A 24 mile long bridge? Why not! Most large scale engineering projects have a number of competing requirements to solve for when choosing a building or fill material. Project budgets should be affordable, materials should be readily available, labor costs should be minimized, and substrate should be stable and unlikely to decay. With its light weight (11 to 45 kg per cubic meter), ease of installation, and stability, geofoam checks a whole bunch of these boxes.

At Maggie Daley Park, one of the project’s defining challenges was to find a material that could sit above an underground parking garage, which could only support a limited weight. In addition, the park’s design brief called for “a complex landscape that offers experiential range” with varied character, scale, and seasonal attributes. To build any kind of varied topography and support the planned winter “ice ribbon” and play spaces, it was necessary to use a fill material that was lighter than soil. Geofoam, at approximately 1/100 the density of dirt, was the obvious solution.

Despite its uncanny appearance, geofoam is incredibly prosaic. Essentially, it’s polystyrene. Expanded polystyrene (EPS) geofoam — the most common type — is made from small polystyrene resin beads that contain microscopic cells filled with a blowing agent, which expand when exposed to steam under controlled pressure and are molded and fused into a brick shape. It’s the same product used for decades to package appliances, keep food cold, and protect delicate shipments. The main difference between geofoam and the foam chunks you discard after you unpack a new refrigerator is the size.

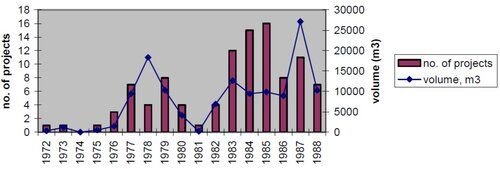

Geofoam made its first appearance in Oslo, Norway in 1972. Installed as a filler in the embankments around the Flom bridge, geofoam proved an effective stabilizer for the soft soil embankments, which had been prone to road-damaging settlement. The project was a success, and geofoam gained significant traction in the mid-to-late 80s. In 1985, Oslo hosted the first International Geofoam Conference, where about 150 attendees from 11 countries shared knowledge about current and potential uses of the product. Between 1985 and 1987, engineers in Japan used geofoam for thousands of projects using an estimated 46 million cubic feet of the product (for context, the Empire State building’s volume is 37 million cubic feet).

Geofoam is just one of many artificial substrates used in construction, landscaping and infrastructure projects. In Norway and elsewhere, shredded tires, foam glass and waste concrete have been used to varying degrees as lightweight fills. But compared with other fill types, geofoam has only become more popular over time, due to its particular combination of desirable properties for construction: lightweight, durable, cheap, easy to install.

As a material that usually lurks below the earth’s surface, popping into view only while it’s being installed or unearthed (or when it features in a semi-viral twitter thread), Geofoam appears at first glance like a hypermodern product: Minecraft made physical, an architectural model in the flesh. It can come as a shock to realize that giant bricks of polystyrene are stuffed below the turf, like silicone implants under the skin of a city. All is not as it seems — below the dirt is not always more dirt.

To extract petroleum from the earth only to refine it into pellets, puff it into bricks, and put those bricks back in the earth feels like a joke about the wastefulness of capitalism. But the environmental impact is complex. Geofoam producers and civil engineers alike laud geofoam for its stability and safety. “Geofoam is not biodegradable and once installed below surface there are no adverse effects on soil and groundwater quality” writes the Geofoam Research Center at Syracuse University (on a website last updated in the early 2000s, by the looks of it). Unsurprisingly, much of the literature on geofoam’s long term impacts come from the construction industry and geofoam producers, the groups most inclined to research geofoam’s properties and longevity. However, as long as you don’t set it on fire (flame retardant chemicals used to treat geofoam were shown to be accumulating in the ground, which led to their discontinuation in Europe but not the US) or pour a petroleum solvent on it (which causes it to dissolve and break down into a non-load-bearing sludge), by all accounts geofoam resists degradation and decay for decades of use.

Geofoam producers and boosters claim that geofoam actually reduces the environmental impact of a project by allowing for shorter construction times, reducing the need for energy-intensive earth moving machinery, and reducing the carbon footprint of the overall project. The other outcome of this streamlined construction process is a reduction in labor. This reduction in labor costs is a boon for investors and project managers, but a loss for the workers that would otherwise be employed for more varied labor over a longer period of time. Geofoam’s universal, lightweight blocks represent a replacement of skilled local labor with globally ubiquitous, easily stackable, building units.

For developers and project planners, though, the benefits of geofoam are undeniable. Its lightweight, modular qualities are ideally suited to the demands made of contemporary urban parks. Seemingly impossible structures become possible — the Little Island project at Hudson River Park makes extensive use of geofoam to ensure the park’s luscious rolling hillocks were light enough to be supported by the delicate concrete support piles. Maggie Daley park can offer space to frolic and picnic above a subterranean parking structure with little fear that the weight of the soil will endanger the garage’s structural integrity. In this way, geofoam abstracts out the particularities of the substructure on which it’s placed, paving over idiosyncrasies and particularities with big white fungible blocks.

As a platform for modular landscape design, geofoam recalls a series of earlier visionary architecture projects — Superstudio’s Continuous Monument and Supersurface. Superstudio, the 1960s–70s Italian architectural firm that responded to the era’s economic conditions and market constraints by not designing buildings, are most known for their conceptual projects that critiqued the state of architecture and urban planning. Continuous Monument comprises a series of drawings which laid white, monumental gridded structures over the natural world and cities alike, bringing a sense of abstract order to unruly landscapes, and creating a sense of “total urbanization.” Supersurface used the same grid to imagine the earth as a continuous plane or platform for living, where resources could be distributed evenly and space became a great borderless landscape. From today’s vantage point, the white grids of Continuous Monument and Supersurface look eerily similar to large-scale geofoam projects. In both cases, the landscape is turned into a modular space where anything can be built or imagined.

Not only does geofoam offer reliability and uniformity with its consistently sized blocks and widespread availability, it also dangles the potential for endless reuse. Geofoam blocks can contain some percentage of recycled plastic, and the blocks themselves are marketed as recyclable (although as with all plastic recycling, “downcycling” is the more accurate term, as plastics can’t be endlessly cycled). Geofoam’s resilience also allows for a more literal kind of cycling — according to the Geofoam Research Center, “EPS blocks exhumed from a construction site in Norway after more than 20 years of burial were found to be in good condition and were re-used.” Indeed, during the construction of Maggie Daley park, crews reused geofoam that had been previously installed in Chicago’s Daley Bicentennial Plaza. Unlike an implant, a geofoam block offers the promise of endless life, lying dormant in the ground until it is exhumed, dusted off, and used again.

What does it mean for space to be continuous, universal, platformitized? Geofoam encourages a sense that landscapes can be both abstracted and immortal, allowing resources to move freely across an invisible yet increasingly comprehensive grid. But landscapes are never truly fungible: place is not a neutral platform. So while geofoam allows for increased flexibility and supremely modular convenience in large scale building projects, architects and engineers alike still have to contend with the specificity of local environments, cultural norms, and land use.

When its blocky white continuity comes into public awareness, geofoam is an easy focal point for critique and even horror. But geofoam is just one of the many manufactured materials we shove underground to support our urban infrastructures and architectural whimsies. Concrete, rebar, and other building materials also have massive footprints and contribute to a range of complex ecological problems. Geofoam’s artificiality is in no way unique. It’s just visually striking, and thus a useful lens for thinking about the built environment. For something so lightweight, it’s laden with meaning and contradiction. Geofoam is the frothy platform that supports greenwashing urban projects and enables labor to be replaced with puffed-up plastic. At the same time, it’s substantive, essential: the increasingly ubiquitous substrate preventing freeways from crumbling and parking garages from caving in.