One of things I like about having young children is that they ask simple questions with seemingly simple answers. That is, of course, until you try to answer them. While running a bath for my son recently, he asked, “Where does this water come from?” Excited by his curiosity, I launched into an explanation that featured reservoirs, water treatment, and pipes. It took me about 40 seconds to realize I had no real idea what I was talking about. I suspect he realized that too, though he humored me with a smile before diving into the bath.

The world is staggeringly complex. There are entire industries, tools, technologies, and ways of thinking that are hidden from me as I have no notion of why they should even exist. For me, Scope of Work is about struggling with that complexity – accepting that there is too much to possibly learn, but having a go anyway.

It turns out that I wasn’t that far off with my impromptu explanation of water treatment and distribution, but I left out the coagulation and flocculation bits. When I get my next chance to talk about water infrastructure with my kid, I’ll be ready.

-James Coleman

The most clicked link from last week's issue (7% of opens) was a video about the Plymouth Tube Company's cold drawn tubing process. In the Members' Slack, the #community-lunch crew has been chatting about prototyping musical instruments, the novel instruments created by Controllerist artists, and the beautiful browser-based synth interface embedded in Robin Sloan's latest short story.

JOBS.

- Charm Industrial is hiring a fabricator in SF.

- ABB is hiring a mechanical designer in Montreal.

- The Maintainers is hiring four fellows anywhere in the world.

- JetZero is hiring an R&D project engineer in Long Beach, CA.

- City Museum is hiring a general maintenance tech in St. Louis, MO.

- More jobs on Scope of Work's job board; you can promote the role you're hiring for here.

SPONSORED.

When Native American artifacts are returned to their rightful owners as reparations, they’re often in poor condition or even poisonous to the touch, as museum curators used arsenic as a preservative. Technology is becoming an important part of restoring artifacts to a usable state. Check out how Jay Loomis, a graduate student at Brown University, uses Fusion 360 and the Formlabs Form 3 to restore indigenous wind instruments.

PLANNING & STRATEGY.

While reading Secondhand in the SOW Members’ Reading Group, I learned about Speed Queen, a Wisconsin based manufacturer of long-lasting washers and dryers. Their machines are highly engineered for endurance and reliability, with the company advertising that they last around 25(!) years. Speed Queen is a subsidiary of Alliance Laundry Systems, the largest maker of commercial laundry equipment in the world.

I think the attempt to engineer long lasting appliances should be celebrated, but there are tradeoffs. Speed Queen machines score low in energy efficiency, for example. To achieve their fabled reliability, they eschew newer technology that might increase efficiency in favor of mechanical systems that are proven to last. This is an interesting tension I’d expect to see highlighted more as we figure out how to deal with climate change. In the Reading Group’s discussion with Secondhand author Adam Minter, he suggested that using life cycle energy analysis, a tool for understanding the full energy cost of a good through its lifetime, to strike the right balance:

Life cycle analysis is art as much as it is science, and everybody can have their own framework for doing it. But I think in general, the frameworks are useful and a positive thing to at least get us to think about the impact of our consumption.

While taking a course on AI recently, I learned about constraint satisfaction problems (CSPs). Basically, a CSP is a way of describing a problem in terms of its variables, and the constraints on those variables. If you pick values for the variables that meet all constraints, the CSP is “solved.” The classic CSP is a sudoku puzzle where the squares are the variables. The player chooses values for each square (1-9) that satisfy the game’s constraints (a number can only be used once in a row, column, or subgrid). Some researchers have proposed approaching Life Cycle Analysis as a CSP. The idea is to model each stage of an object’s lifecycle as a set of variables and constraints, then use algorithms to minimize environmental impacts while satisfying cost, reliability, or performance goals. For appliances, one could imagine a CSP solver that warns a design engineer that the component they have added to the bill of materials will decrease durability, or surpass lifetime energy usage targets.

Structuring a problem as a CSP is broadly useful. The Hubble and James Webb space telescopes, for example, use CSP solvers to distribute viewing time to scientists – a fairly complex problem, as constraints like spacecraft orientation, timing, sun avoidance, and earth “occultations” need to be managed. Closer to earth, job shops can use these algorithms to schedule resource usage, allowing work to be completed on time.

MAKING & MANUFACTURING.

I recently became aware of the Statue of Unity in Gujarat, India. Completed in 2018, it is the world’s largest statue, standing at 182 meters tall (excluding its 58 m base). This is more than quadruple the size of the Statue of Liberty (42 m) and 50 m taller than the previous record holder, the Spring Temple Buddha in Henan, China (128 m). The Statue of Unity honors Vallabhbhai Patel, the first Deputy Prime Minister of India and an important leader in the nation’s independence efforts.

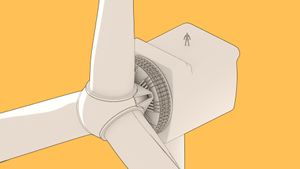

This video gives a good overview of the statue’s construction. It is basically a skyscraper shaped like a person, featuring two massive cores made from 210,000 m3 of concrete and a skeleton made from 27,000 metric tons of steel. The monument is so tall that it has two tuned mass dampers (which you can see in this video) to help mitigate wind and seismic activity in the area.

Indian sculptor Ram V Sutar meticulously crafted a 10 m reference design, which was 3D scanned and cast into 12,000 bronze panels by Chinese firm Jiangxi Tongqing Metal Handicrafts (whose foundry you can see here). This sourcing choice was not without controversy, as the monument was in part created to support a “Make In India” campaign.

MAINTENANCE, REPAIR & OPERATIONS.

Roughly twice a year, a utility worker drives up to my house and begins digging around in my front yard. Usually, a neighbor’s cable line has been accidentally cut and they need to locate the lines (which run under my yard) to make a repair. The workers are efficient and polite (as you would need to be when randomly digging holes on a stranger’s property), but it struck me as odd that this happens so often. Isn’t there some sort of utility map?

It turns out that there isn’t – at least not a reliable one. This great piece gives an overview of the “utility-locator” industry, which is responsible for finding the millions of miles of telecom, water, gas, and power lines that are located beneath the ground. You’ve no doubt seen the spray paint and flags that they place while doing their work. It seems that it is more cost effective to send these polite folks to locate the lines rather than maintain an updated map.

The industry even puts on an International Utility Locate Rodeo, where the most talented practitioners compete in 12-minute sprints to locate hard-to-find infrastructure. It's pretty fun to watch, in an umarell sort of way.

DISTRIBUTION & LOGISTICS.

Like many of you, my family receives a pile of cardboard boxes on our doorstep each week, given our reliance on e-commerce to get things we “need.” When we get around to opening the boxes, we generally take them directly to our recycling bin. This has always felt a bit wasteful to me.

At one point in my career, I helped design the logic for how a distributor chooses which boxes, and how many of them, to use when shipping orders. The basic goal is to get the stuff to the customer without damage, while reducing the cost of doing so. One way to reduce cost is to ship fewer boxes, combining more items in a single container – but this slows down the shipping process. Partial orders need to be staged somewhere to wait for the remaining items, causing them to miss the complex symphony of carrier cutoff times, delaying delivery.

Another way to reduce cost is to reduce the amount of packaging material used – to choose boxes that fit their contents better. At one point or another, we’ve all received absurdly small items in oversized boxes, and wondered what the retailer was thinking. Ideally, each shipment would have a box that is perfectly shaped to its contents. But if you have more than a few SKUs, the combinations become intractable. It is surprisingly difficult to optimally pack a container, because the number of ways to combine items grows exponentially with each item you add. In computer science, the “bin packing problem” is considered np-hard, which basically means even computers have a hard time solving it. Even if you settle for “nearly optimal,” your packing operations could slow to a crawl. There are machines that make custom boxes on demand (video here), but they are more suited to single, regular-shaped items that don’t require packing protection. You would also need quite a few of them to handle high velocity shipping environments, which would be costly in terms of equipment and space.

Amazon and others have invested significantly in machine learning to make packaging decisions in a more automated way. Another solution, of course, would be for customers to accept slower shipments, something that some retailers allow. But it is still tricky to find the right balance.

Related: This NY Times piece on cardboard manufacturing is beautifully photographed, and brought back fond memories of tackling these problems.

INSPECTION, TESTING & ANALYSIS.

I really enjoyed the FIFA Men’s World Cup this past December, and followed the introduction of new tracking technology that would make offside calls more accurate, transparent, and ultimately less controversial. FIFA worked with a company called Kinexon, who also makes industrial asset tracking systems, to introduce a new sensor-laden ball that enabled “semi automated offside” decisions. Referees ultimately made the final call, but with a whole lot of assistance from sensor-powered AI.

Each ball contained an ultra-wideband sensor for precise positional data and an inertial measurement unit for detecting angular velocity and acceleration. The sensor data (polled at 500 frames per second) was combined with player position data provided by a 12-camera Hawk-Eye system to help make the sometimes razor-thin decision about whether or not a goal should stand.

The system is supposed to be faster than traditional video-only review methods, and my sense is that it performed fairly well. Still, many soccer fans complain about the introduction of these tools as they feel it slows the game down. Without them, referees make the decision in real time; if they don’t raise their flag, the goal stands. Now, there is uncertainty because the Kinexon system can intervene. Referees sometimes get it wrong, but many prefer the occasional error to the specter of uncertainty.

SCOPE CREEP.

- A delightful story about a reporter who discovers his wife is one of the best Tetris players on earth.

- A fascinating interview with John Carmack, the legendary video game programmer responsible for Doom and Quake. After leaving his CTO role at Oculus VR, he has turned his attention to, of all things, creating artificial general intelligence.

- An ingenious commercial for the Nissan Leaf that imagines a world where everything is gas powered.

- 20 mechanical principles combined in a useless Lego machine.

Thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible. Thanks specifically to Nick Fountain, Corey Menscher, and Stu Sonatina for directing me to cool parts of the internet.

Take care of yourself,

James

p.s. - We care about inclusivity. Here’s what we’re doing about it.