The quiet crackling sound of a lamp turning on gives way to the hazy but articulated glow of neon, which has illuminated downtown horizons for over a century. The arc of the neon sign traces scientific advancement through to commercialization, ubiquity, and then nostalgia. Through these phases, neon signs have been given shape and color by the tradespeople who make, install, and maintain them. As I learned in the workshop of Arleigh Schray, a glass bender in Albuquerque, New Mexico, glass bending is a delicate and detail-oriented job, drawing on a blend of scientific knowledge and the feel-by-touch that only comes from practice.

In Flickering Light, Christoph Ribbat describes how, “using their breath, mouths and hands and all their own acquired knowledge and skill… the neon tube brought the handmade object back into the city.” In this way, the hand of glass benders is inscribed on the storefronts and skylines of the communities they work in.

Today most of the glass bending schools that sprouted up in the first half of the twentieth century have closed. But some of those iconic signs remain, and if they continue to remain, they will continue to be repaired, recharged, and remade by people with an increasingly rare set of skills and supplies of hollow glass cylinders and gleaming electrodes.

Discovery of neon

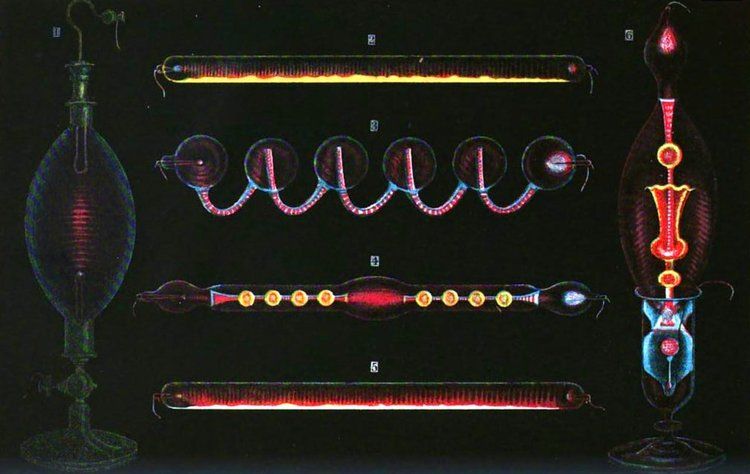

The creation and commercialization of neon signs in the early 20th century was undergirded by a series of scientific discoveries and new technological processes, beginning with experimental observations by Michael Faraday in the late 1850s. He applied a voltage across an egg-shaped flask, emptied of air, and saw that the color of the spark depended on the type of gas present in the flask. This observation informed the new science of spectroscopy, enabling scientists to identify an element with certainty based on the wavelengths of light it emitted or absorbed. In the 1890s, the chemist Sir William Ramsay and his colleagues Lord Rayleigh and Morris Travers used spectroscopic techniques to scour the air for unknown elements, beginning with one that stumped them with its refusal to combine with other elements. They discovered the unreactive noble gases. While an application wasn’t immediately clear, Travers was stunned by the beauty of neon, and later reflected:

The blaze of crimson light from the tube told its own story, and it was a sight to dwell upon and never to forget. It was worth the struggle of the previous two years; and all the difficulties yet to be overcome before the research was finished . . . for nothing in the world gave a glow such as we had seen.

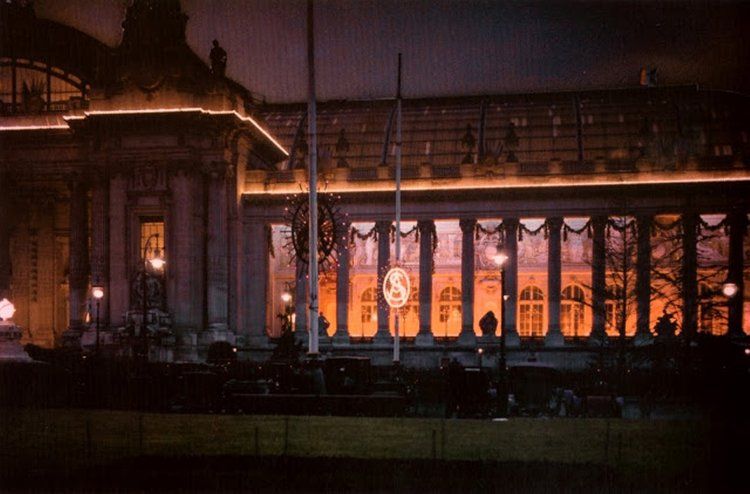

Several decades later, a French scientist and entrepreneur named Georges Claude began liquefying large quantities of air, both for industrial purposes (to produce liquid oxygen, nitrogen, and argon) and in hope of discovering additional noble gases. Neon was a byproduct of the process of liquefying oxygen, and Claude looked for a way to make use of it. He had a distaste for the hot incandescent commercial lighting preferred at the time, and saw a market for something more alluring. Existing objects called Geissler tubes demonstrated the principles of electric glow discharge in decorative forms and colors. Commercially available Moore lamps also used electric charge passed over a gas-filled glass tube to produce electric light, but were not hugely popular, due partly to the difficulty of installation and their tendency to break. He improved upon Moore lamps – switching gases from nitrogen or carbon dioxide to neon, and adding a carbon filter and larger electrodes – and demonstrated the first commercial neon sign at the Salon de l’Automobile in Paris in 1910.

Claude formed the company Claude Neon to sell signmaking franchises globally, and others soon followed. While he hung onto a monopoly through the 1920s, the trend toward neon signage gradually took hold in cities around the world. Patents expired, and knowledge of the trade began to circulate widely. Schools were established to teach glass bending, and cities and streets became identified with the neon glow of their most iconic signs.

The golden age of neon

In the twenty-five years following Georges Claude’s demonstration, the neon-sign industry in the United States grew to an annual business worth around thirty million dollars. In 1933, the Sign Permit Bureau of New York documented 16,254 installations of outdoor electric signs in the Boroughs of Manhattan and Brooklyn alone. The following year saw an increase of 20 percent: 19,550 signs installed, and of those, “no less than 90 per cent of all the signs installed were of the luminous-tube, or "neon," variety.”

The golden age of neon signs in the 20th century supported a global network of local artisans. Because thin glass tubes are fragile, neon signs have historically been made near the sites of their eventual display. Large companies, smaller manufacturers, and independent craftspeople could all find a place in the market.

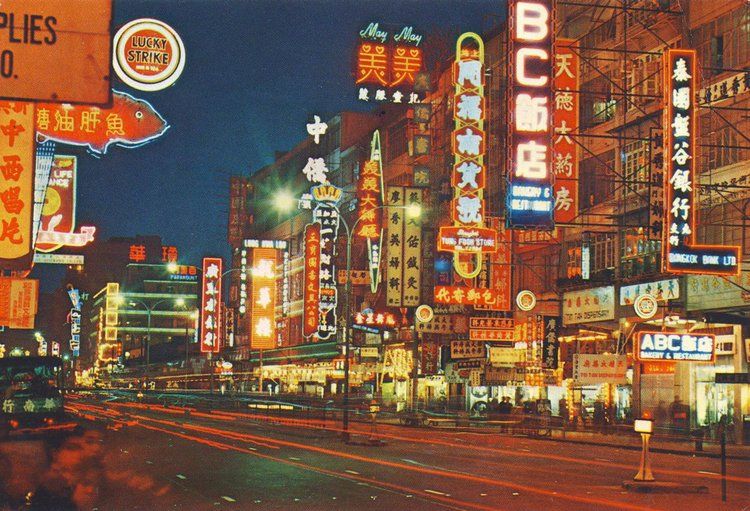

Neon signs are (or were) a global phenomenon, made at a local scale, as characteristic of the streetscape in Hong Kong as in LA or New York City. The neon advertising sign faced its first decline in the stock market crash of 1929, its second in the purposefully darkened skies of the Second World War, and its third–and most prolonged–decline beginning in the 1960s, when it began to be seen as old-fashioned. But in between and after each decline, desire for neon has rallied or resurged. The lights never all go out at once.

Even now, the stretch of Central Avenue that was historic Route 66 in Albuquerque, takes on a new character at night as the luminous tubes flicker on. Motels that looked washed up and empty during the day are now beckoning, drawing the eye. Signs that hardly stood up to the sun, or faded into the chalky pastel bricks and stucco, become visible again in twilight. Some of the neon signs are old, some are out, some are newly restored. All of them have that distinctive luminescence.

Making modern neon

While neon signs are long past their peak, the local networks of neon makers endure today. Arleigh Schray is mostly self-taught, with technical knowledge obtained from the public library. When she was getting started in the 1990s, the closest glass-bending school was in Irving, Texas. “You could do an eight week course, eight hours a day,” she told me, “but if you don’t have a shop to go back to, you lose it.” The craft takes constant practice. Arleigh found a local glass bender willing to take her on as an apprentice, so she left the dentist’s office she was working at, got a job at Costco, and spent her days off at the glass bending shop. Eventually, the unpaid apprenticeship turned into a job paid by the piece, and then something steadier. She took a job with an established sign maker in Albuquerque, and when he wanted to retire, she bought him out of the business. Over the course of four years, she worked at the shop and made her former mentor payments toward the tools and stock. It became hers.

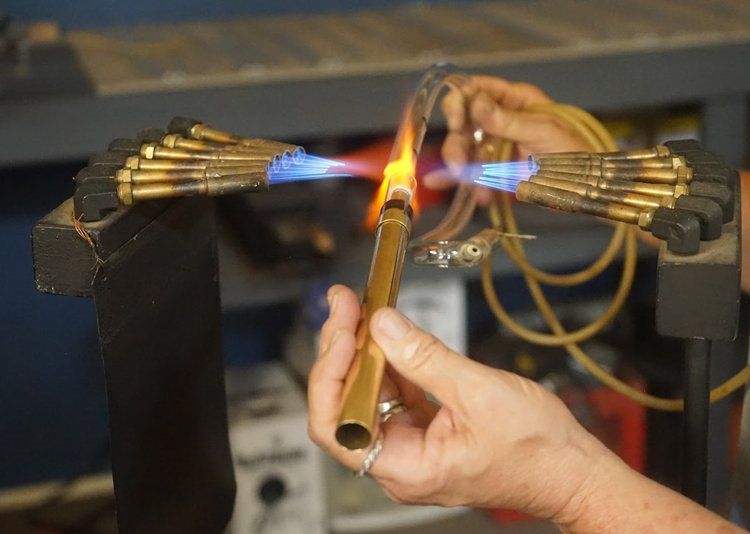

Now Schray works in a small shop by herself, with a large table in the center where patterns are laid out. Glass tubes of different diameters are stored beneath the tabletop, and the various torches are spaced throughout the room so that one person can move safely and fluidly from one flame to another while holding a hot length of glass. In the early years of her career, Schray navigated much larger workshops, where multiple glass benders worked simultaneously. Now, her tool setup is optimized for a single craftsperson. But the signs haven’t shrunk–on the day I visited, she made the curlique dot of an ‘i’ about as long as my forearm.

Each neon sign begins with a glass tube, heated and bent carefully into shape. The sections of glass to be bent are heated individually in the flame of a hand torch, crossfire, cannon fire, or–for the large curves for arches or circles for letters like B, R, and S–in a ribbon fire. When the glass bender feels the desired level of pliability in the heated section of glass, she gently and quickly makes the bend. She references and lays the glass over a pattern hand-drawn or plotted on paper, and presses the bent glass with a flat stone to ensure that the script flows across a level plane. Letters and shapes are bent in reverse, mirror images of what they will be, Schray said, “so when you turn it face-out, it’s exactly how it’s supposed to look.” If you wanted to learn this part on your own, you might find yourself here, taking notes on correct reversal technique and bend shapes.

An electrode is welded to each end of the tube, one before the glass is bent and cooled and one after. The assembled tube and electrodes are then bombarded with electrical current to clean their surfaces, evaporating unwanted surface material and any impurities or oils left by handling.

After bombardment, the tube is ready to be filled with the gas that will give it color when lit. The color of a finished neon sign or lamp is a collaboration between the gas inside, and the glass it’s made of: some glass is colored (the classic colors are red, green, and blue), some is clear, and some is powder-coated on its interior with color that comes out only when lit.

Networks of production

Careers like Schray’s depend on myriad relationships within a limited geographic area, both lateral connections with clients and bigger sign makers and longitudinal connections with mentors, apprentices, or (as in Schray’s case and others) older, retiring business owners. Hillary Predko has written previously for Scope of Work that “fostering the ecosystems, businesses, and communities that make up the domestic manufacturing sector… means paying attention to what is in place and bolstering local needs.” In a manufacturing ecosystem that is geographically contained by the fragility of the final product, bolstering local needs means ensuring that there will be someone with skills and equipment nearby to replace the gas in the burned-out sign. Arleigh Schray remains a busy one-woman show. Repairs for bid sign companies are the bread and butter of Schray’s Neon Glass Works. She’s a glass bender only: doesn’t go on site, doesn’t do installations. Much of her work comes in from other sign companies, many of which don’t keep the level of in-house glass bending staff they once did. In Flickering Light, Ribbat noted that 1950s Philadelphia was home to around 40 neon signmakers, blowing, shaping and filling the glass tubes. By 1989, there were only six, “and five of them were old enough to be retired.” Schray told me when I visited her shop that components and materials are harder to come by than they once were because many of the suppliers she’s used over the years have shrunk their neon-related offerings in response to diminished demand.

The future of neon

Safety concerns (sometimes reflected in building codes) and maintenance costs have led to a phaseout of true neon lighting in many places. It’s replaced most often by flexible LED tape in colors meant to evoke nostalgia for real neon signs. Improvements in the energy efficiency of LEDs have also contributed to the shift: although keeping a neon sign lit is far less energy intensive than using fluorescent or incandescent light, LED lights require even less electricity. However, Evan Gillespie notes that “comparisons, which often claim a 90 percent energy savings for LED, often fail to take into account the relative inefficiency [in terms of brightness] of LED light sources as compared to neon… Adjusting the brightness of the LED for comparison to neon, the difference in power consumption is less pronounced.”

There’s still desire for traditional neon signs, and there will continue to be old signs worthy of repair, and needing the skills of glass benders. “It goes in cycles, like everything,” Schray told me, reflecting on the recent resurgence of neon lettering—both in art, where it has remained a popular mode of communication (see Tracey Emin, Bruce Nauman, Lili Lakich) and commercial decoration and advertising. Recontextualized as artifacts of Americana, or nostalgic emotion, neon signs are somewhat popular with people who want that glow inside their homes. For this market too, LED signs compete: flexible LED tape can be mounted and curved into signs resembling neon, and can be shipped across the world. New variants of LED tape continually improve upon older ones in flexibility and brightness. Innovations in manufacturing techniques, like those Big Clive explores in a video on the design and manufacture of a “new and interesting miniature variant” of LED tape, have helped prices plummet for some varieties of LED tape in a way that hand-bent glass tubes can’t beat. Thrift and ubiquity are no longer the hallmarks of real neon signs.

There was a time when neon became so commonplace that it lost its specialness and almost came to represent something cheap or tawdry. Now it’s undergoing a nostalgic revival. There was a time, too, when we had red LEDs and green LEDs and no blue LEDs, and the sought after blue, once developed, became a sign of the future (its inventors won a Nobel prize in physics). We are less astonished than we used to be by manmade light, just as we long ago became less astonished by the tint of purple extracted from dye-producing sea snails, a pigment that was once more expensive than gold. Certain colors enchant, not just because they are new, but because of the thrill of scientific labor and discovery that set them on stage. The process of discovery and refinement may be fraught, difficult, with much to overcome. But it holds a possibility: “for nothing in the world gave a glow such as we had seen.”