Twice a year, an HVAC technician named David visits my house to do maintenance on our air conditioner and furnace. On a visit in late spring, he reported that the refrigerant in the AC was low and that he had to “top it off” in order for the house to cool properly. Refrigerant lines are supposed to be full, closed systems. If the level was low, it was likely because of a leak somewhere, which was bad news. Based on his experience, it would need to be replaced within a season or two, a project that might cost as much as a used Honda Civic.

The silver lining was that I had some time to figure out what I wanted to do. People usually call David because their AC isn’t working at all. If the issue isn’t fixable and they’re in the middle of a sweltering Georgia summer, the homeowner needs to make a complex set of decisions very quickly. David also drives a hard bargain in the summer, because he has lots of other customers waiting to get their ACs fixed. I could now (1) deliberate on the type of system I wanted and (2) choose the time of year to install it.

I chose to tackle the project last month, just as moderate fall temperatures set in. After the boom times of summer, work slows down for HVAC contractors like David, and they offer steep discounts. As for the type of system, I knew only one thing at the outset: I wanted a heat pump.

This is primarily because we read Electrify, by Saul Griffith, in the Scope of Work reading group last year. In it, Griffith argues that one of the best ways to reduce a household’s energy needs and carbon footprint is to install a heat pump for heating and cooling. According to Rewiring America (a nonprofit Griffith started), 98% of US households would reduce carbon emissions by installing a heat pump. This sounded like a pretty easy win for me. Electrify didn’t go into the technical details of how heat pumps work and, to be honest, I didn’t even know what a heat pump was. But this seemed like the right time to figure it out.

The first thing I learned was that I already had several heat pumps in my home. I thought a “heat pump” was a specific type of appliance, but it's really a technology that is used in a broad range of appliances. The existing AC that David serviced was a type of heat pump. The climate control unit in my car has a heat pump. My refrigerator is a heat pump too, and studying it helped me to figure out how the technology works generally.

I intuitively believed that my fridge “made” cold air, but that turns out not to be the case. In reality, it uses electricity and clever engineering to move heat from inside the insulated box to outside (e.g. your kitchen). How does it move heat? It leverages physics. The second law of thermodynamics states that heat moves from hot areas to cold areas. Another way of saying this is that heat flows down temperature gradients. To move heat from the inside of a fridge to the outside, you’ve got to create temperature gradients for the heat to roll down.

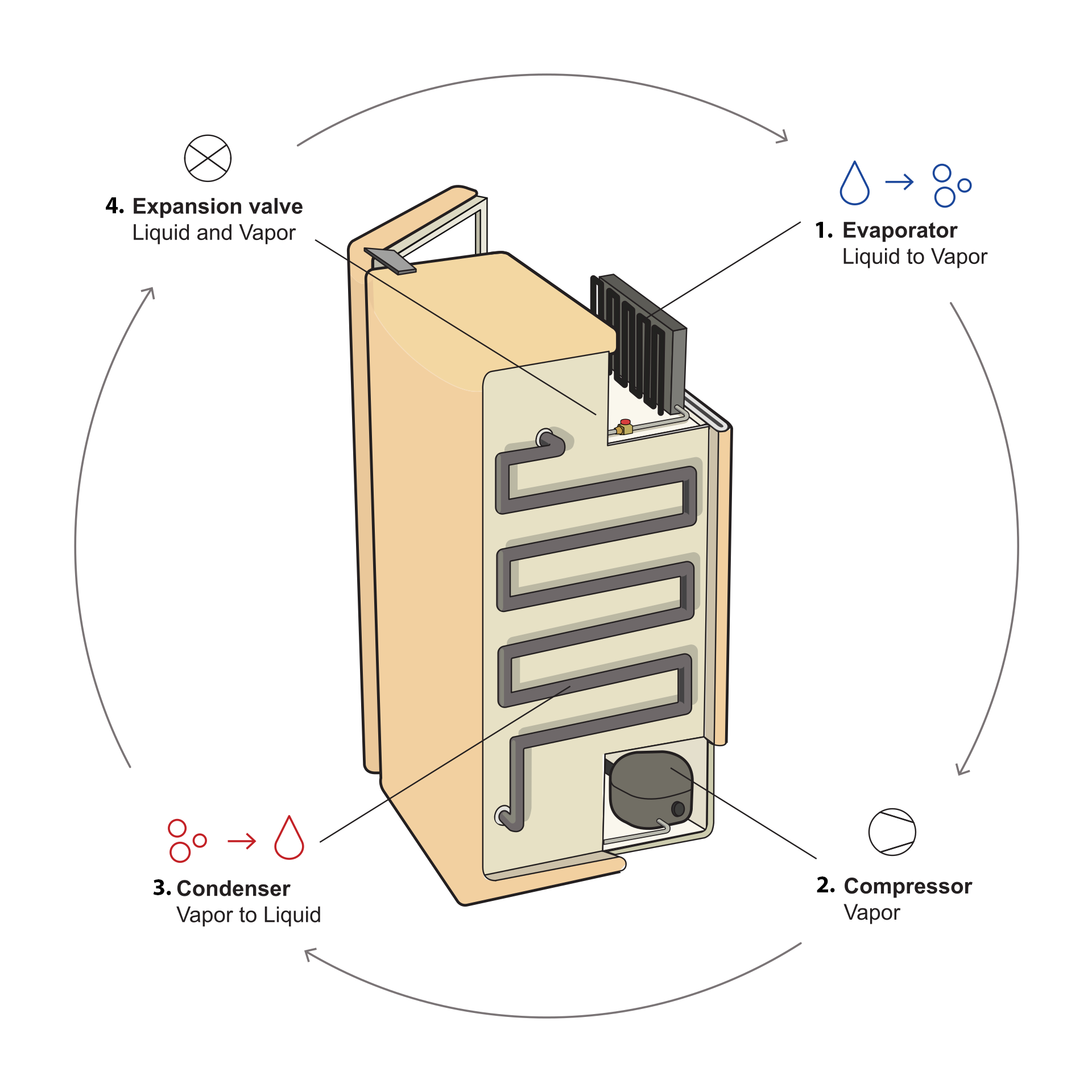

Nicola Twilley’s excellent Frostbite (Chapter 2) discusses this well, but here is an overview of how it all works:

- The process is enabled by a refrigerant like R-134a, which boils at very low temperatures (-26.3° C). Inside the fridge, the refrigerant enters something called an evaporator unit at low pressure, as a cool liquid. It absorbs heat from the inside of the fridge, causing it to boil and become a gas. This is the first temperature gradient: Heat rolls from the inside of the fridge to the refrigerant, heating it up and turning it into a gas.

- The refrigerant gas leaves the insulated part of the refrigerator and flows into a compressor, where it is pressurized. This increases its temperature even more, making it hotter than the surrounding room.

- Next, the hot, high-pressure gas moves into a condenser unit, typically located behind the fridge. Here, the refrigerant releases the heat it picked up earlier. This is the second temperature gradient: Heat rolls from the refrigerant to the air behind your fridge, causing it to feel warm.

- Finally, the refrigerant passes through an expansion valve and back into the fridge, which reduces its pressure and further cools it down. It returns to the low pressure, low temperature liquid we began with, ready to capture more heat on the next cycle.

I mentioned that my house already had an AC, and that this is a type of heat pump. Why did I need another one? Just as with a fridge, ACs are designed to move heat in one direction, from inside an insulated box to outside. The AC’s box — a building — is a lot bigger than a refrigerator, but the principle is the same: Heat always rolls from inside the box to out. With a home heat pump, the addition of something called a reversing valve allows it to work in either direction, bringing heat inside during the winter or releasing heat outside during the summer. If you’re curious about some of the details or want to see the actual components, I highly recommend this video explainer from This Old House.

I had been using a methane gas fired furnace to produce heat during the winter. Installing a heat pump meant I could get rid of the furnace, and eliminate my direct reliance on fossil fuel (completely removing reliance on carbon would require clean electricity). By doing this, I’d be making my home much more energy efficient. Climate experts love this aspect of heat pumps, with some models exceeding 300% efficiency. This is because they don’t generate heat directly, like my furnace does; instead, a heat pump uses a small amount of electricity to move heat in the way I described earlier. Heat pumps were once thought to work poorly in places that freeze frequently, but the technology has improved considerably in recent years. Cold-climate heat pumps can work well at temperatures as low as -15° C. It feels counterintuitive, but there is actually plenty of thermal energy in the air to harvest, even on cold days.

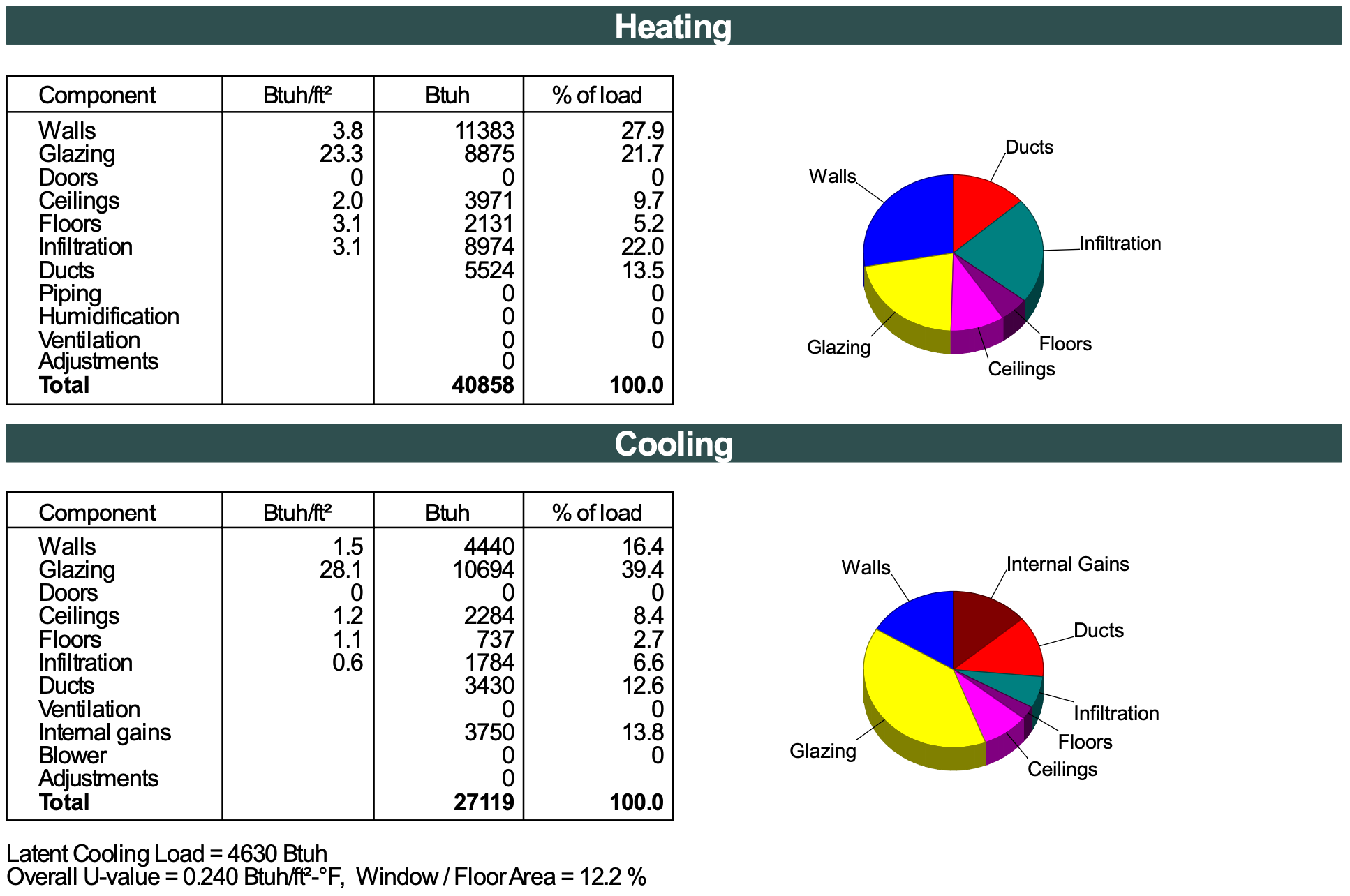

I interviewed several HVAC contractors, and used this list of vetting questions to narrow them down to one. I chose my contractor primarily because they were the only one that offered to do a Manual J load calculation before designing my new system. Manual J is a standard, set by the Air Conditioning Contractors of America, for determining the optimal size for a heat pump, air conditioner, or furnace. Choosing a system of the correct size is important. If the system is too small, it won’t heat or cool the home to the expected levels. Systems that are too large are also a problem. They reach the expected temperature quickly, but don’t run long enough to remove humidity from the air, resulting in less comfort. Oversized systems result in higher energy bills and shorter system lifespans as well.

I was impressed by the technician’s thoroughness during the analysis. Over the course of an hour, he measured everything about my home related to heating and cooling. This included measuring floor space, evaluating insulation type, noting ceiling height, and cataloging the number, sizes, and placements of all of our windows. He even considered the building’s orientation to account for sunlight exposure. The result was an extensive fifty-page report that precisely determined the size of the system needed to satisfy our baseline comfort objectives for both winter and summer.

Having determined the right system size, a designer worked up a series of options that would achieve my comfort needs. Because I had an existing central duct system to distribute air, it made sense to pick a system that would leverage it. (Mini splits, which are great for retrofitting homes that don’t have air ducts, weren’t a great choice for me.)

This left two big decisions. First, I had to decide if I wanted a single-stage, dual-stage, or variable (inverter) system. These terms refer to how flexibly the heat pump’s compressor operates. A single-stage system operates like a light switch, turning the compressor either on or off. If it needs to change the temperature in your home, the compressor turns on full blast until it reaches the desired temperature, then turns off. Single-stage systems are the most affordable install option, but are relatively expensive to operate. Slightly more expensive dual-stage systems offer increased efficiency by adding an additional compressor setting (off, 50%, and 100%). Variable (inverter) systems operate like dimmer switches, matching the compressor’s activity to the current temperature needs. Variable systems can be expensive, but they are extremely efficient. I chose to install a variable system as I believed I’d get back most of the cost premium over the system’s fifteen-year lifespan. To be honest, though, I also just wanted the coolest gadget – and was grateful for the off-season discount. The biggest downside was that I could no longer use my Nest smart thermostat because it doesn’t take advantage of a variable system’s features.

Next, I had to decide which heat pump manufacturer I wanted to go with. One system that came up repeatedly in my research and conversations with contractors was the Daikin Fit. The Fit is a compact heat pump with a variable inverter. It looks strange, as the discharge fan is on the side of the unit, rather than the top. This, apparently, allows it to be more space efficient and avoid debris falling in the system.

Daikin, a Japanese firm, is the largest manufacturer of HVAC equipment in the world. In 2017, they built a 393,000-square meter plant in Waller, TX, the third largest factory of any kind in the United States (behind Tesla’s Austin Gigafactory and Boeing’s Everett Facility). It houses research and development, distribution, and manufacturing operations, and has a line specifically devoted to the Fit. Heat pumps are fairly complex systems, so the assembly line process closely resembles vehicle manufacturing. The units travel on a conveyor, and at each station, a component is added, modified, or tested. You can get a glimpse of the assembly process in this (very enthusiastic) behind the scenes tour or this recruitment video, which features a conveyor “ride along” with one of the pumps.

I ultimately chose a Carrier Infinity variable system, which qualified for tax breaks in my region. Many heat pumps do, but it can be tricky to figure out if a particular system qualifies in your geography. Your HVAC contractor should be helpful with making a choice to maximize tax benefits.

Two weeks in, no one in my household has complained about the temperature, which I consider a significant early victory. I also feel some pride that I’ve taken a meaningful step to reducing my family's emissions.

SCOPE CREEP.

Read the full story

The rest of this post is for paid members only. Sign up now to read the full post — and all of Scope of Work’s other paid posts.

Sign up now