On the unfinished nature of kitchen knives

I remember the first really sharp kitchen knife I used. At the time, I was a pissant stagiaire without a knife to my name, and this knife belonged to a piratical sous chef named Ho. Ho wanted me to cut a case of oranges for marmalade, the sort of task you give the stagiaire to keep them out of your way. But he also wanted the slices crisp and consistent, not torn off the orange with one of the kitchen’s beater knives, which even though the restaurant was only a month old, were already dull enough for a small child to play with. Therefore, he let me use his knife.

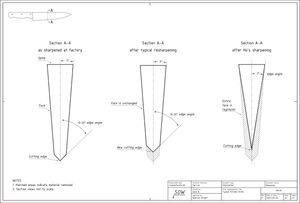

Ho’s knife was not a normal knife. It started life as a standard 10” European chef’s knife, but by the time I used it, there was no distinction between the cutting edge and the face. Ho had ground that angle away, along with a considerable amount of the body of the knife – a brutal refinement.

Even at the time, that knife, with its matte gray face and triangular profile, seemed like a child’s drawing: simple, pointy, somehow essential. It was as though Ho had a vision of sharpness in his head, and tried to make his knife like that: a plain, unburdened wedge, as thin as possible. It turns out he wasn’t far wrong.

In theory, the sharpest knife conceivable would have “one atom at the edge, and two stacked behind it, then three, and so on, so that you have a perfect pyramid the width of a single atom at the edge, moving backwards to something preposterously thin, like the width of a sheet of paper.” This description came from a plainspoken blacksmith named Shehan Prull.

Shehan looks entirely ordinary, as though he weren’t one of only a few thousand people on the planet earning their living making knives by hand. His appearance belies how radical his practice is: he’s one of maybe a few hundred knife makers who perform the entire process by themselves, from unwrapping the raw billet of steel to wrapping the finished knife. He begins by forging the billet into a blank, heating and hammering the steel repeatedly until it’s approximately the shape of a knife, then quenching it to harden. Having accumulated a number of blanks, he’ll use a powered grinding wheel, a ceramic waterstone almost a meter in diameter, to establish the face and cutting edge, before finishing the sharpening and polishing by hand, using flat waterstones like the ones I use at home. Finally, he’ll fit each blade with a handle, a process he says is often given insufficient attention in Japan, though it’s sometimes raised to the level of a fetish by the use of exotic woods and other materials. In the major centers of knife-making, each of these steps is handled by a different artisan, sometimes a different business altogether – in Japan, grinder-smith relationships can last generations. Factory-made knives undergo the same basic steps, though sometimes in different order. Blade blanks tend to be cut or stamped from a sheet of steel, not forged; handles may be welded on, or otherwise fitted before the knife is ground.

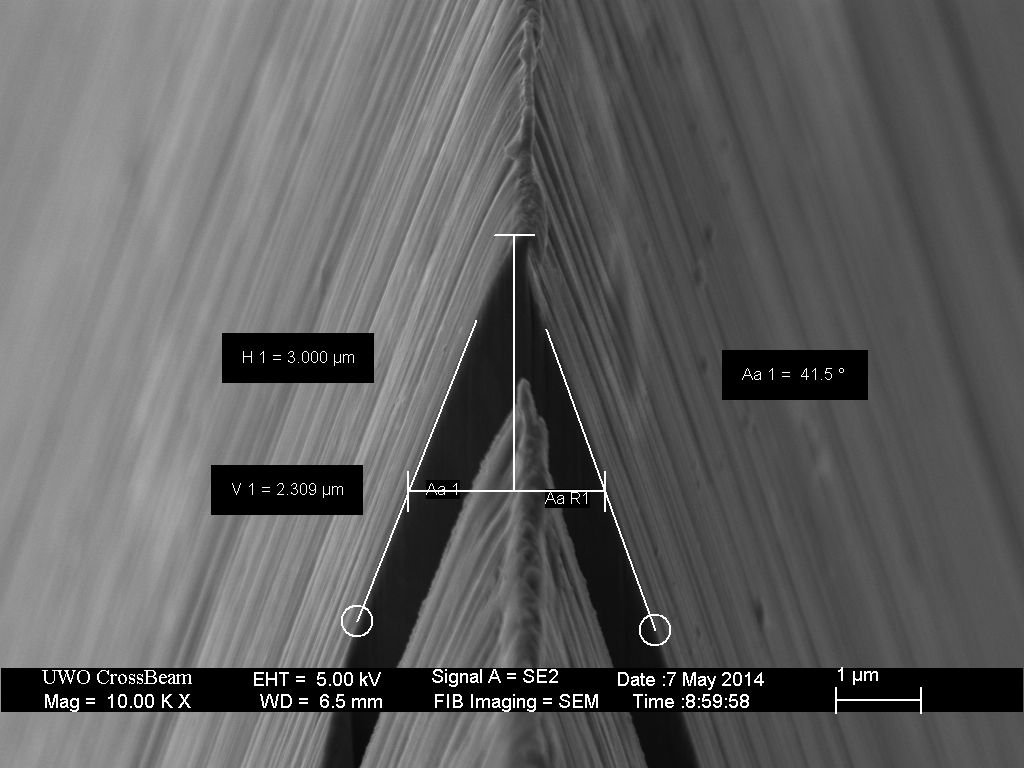

Geometry might be the most explicit description of sharpness we have. If you dig into the internet community of knife nerds, you eventually get to websites with pictures of cutting edges taken with an electron microscope, and measurements of edge thickness and angles. They’re trying to quantify the geometry of some very sharp edges – of surgical scalpels, razors, and high quality kitchen knives. These blades are made sharp in order to be precise, so it seems fitting that to gauge their sharpness, we measure their geometry with as much exactitude as we can muster.

But when Shehan starts forging a knife, edge geometry isn’t what’s foremost on his mind. He’s trying to create good kireaji, a Japanese term often translated as “cutting feel,” though I prefer Shehan’s version: “a tactile type of sharpness.” Kireaji is as much about the molecular structure of the steel as it is about geometry, and it’s here that Shehan’s world intersects with the people with electron microscopes. Perhaps the most important characteristic of the steel is not how it constrains the tradeoff between ductility and hardness, but whether it’s “prone to forming an edge that cuts.”

You might say that some steels just want to be sharp. Cheap stainless steels have “a gummy, stringy character” (several people I spoke to used these exact words) but Japanese white steel (more commonly referred to as shirogami) feels crystalline, and disintegrates into a fine powder when you sharpen it. The character of the steel is only partly set by its formula and the mill in which it was made. It’s finalized by the processes of forging and hardening, of heating the steel and pounding it, making it not just into the form of a knife, but into a substance that wants to be sharp. To do this, a knife maker needs an intuitive understanding of ferrous crystallography – an electron microscope in their head.

This view of kitchen knives, as being engineered almost on a molecular level, naturally suggests that knife sharpening is a similarly exact activity. In this view, each aspect of the geometry of a knife is set, with purpose, by its maker. Some manufacturers use a robot arm to sharpen each blade in exactly the same way – they clearly believe in the utility of the edge angle they set, in some underlying geometric foundation of sharpness (which nonetheless differs from one maker to another).

If there is such a thing, some answer to knife, the universe, and everything, it might be 17°, which is a common benchmark for the edge angle on Japanese-made chef’s knives. “A lot of people come in really tense, worried about drifting off that 17° angle.” I’m speaking to Evan Atwell and Ryan Perrier, the owner and GM, respectively, of Strata, a knife shop in Portland, ME. In addition to selling knives and kitchenware (everything from hand-forged pans to a free-standing wood stove), they offer classes for the novice sharpener and sharpening services by the inch.

One aspect of the classes, they say, is “trying to get rid of that rigidity.” The rigidity comes about partly through nervousness, because the edge angle on many knives is actually hard to find. Many western-style knives leave the factory with an almost microscopic bevel on them, too small for most amateur sharpeners to find and hold. Ho solved this problem by creating an unmissable edge, one which occupied the whole face, so that he could sharpen the edge by laying the entire knife flat upon the stone.

My own early attempts at maintaining my knife’s precious factory-set bevel could most kindly be described as ham-handed fumbling. Eventually, my sharpening action became consistent enough that my knives (I had a Global chef’s knife by now, and sharpened my partner’s Global knives as well) developed a new edge angle, and a bevel wide enough to find easily. I have no idea what its angle is.

But if you watch a Japanese knife grinder putting the initial bevel on a blank fresh from the forge, there’s a conspicuous absence of guides, angle checkers, or really any precision instrumentation at all. It’s just someone holding a piece of steel against a big, spinning rock. Viewed this way, a knife is less a collection of angles, and more a set of intentions. A little convexity to the face, perhaps, so the knife throws the food off as it cuts. Strong distal taper (a change in thickness from the handle to the point), so a pull cut feels like it’s disappearing through the food.

I’ve come to think this is the kind of geometry that actually matters in a kitchen knife: not the profile of the edge, but the shape of the whole. Walk into Strata and you’ll be confronted by a wall of knives, a periodic table organizing what seems like every conceivable blade, every possible combination of length, height, curvature and taper. Shape is a matchmaker. A knife with good kireaji can nonetheless feel clumsy and obstreperous if applied to the wrong task. A sharp edge doesn’t matter if the rest of the knife argues.

How sharp did Ho want his knife to be? How sharp does anyone want their knife to be when they lay it upon a stone? Sharpness has no unit of measure, so the sharpness of a knife is measured only by what it can and cannot do. A knife sharp enough to slice oranges. To pass through tomato skin without skating. To find and slip through the soft spots between bones.

Once you move past the cliches of razors and scalpels, the most meaningful metric of whether a knife is “sharp enough” might be whether it’s sharp enough to produce good food. But this metric is rooted in what the philosopher C. Thi Nguyen calls

a bias which prefers the aesthetics of objects over the aesthetics of processes, which translates, in the world of food, to a bias towards the aesthetics of finished dishes over the aesthetics of the activity of cooking.

My favorite example of this is chives. Turning a bunch of chives into near-microscopic pieces is one of those tasks that absolutely requires a sharp knife, and line cooks in fine dining restaurants learn to take chives Very Seriously. In seven years of running a fine dining restaurant, I never once heard a guest comment on the neatness of the green flecks atop their dish – but it’s such a pleasure to feel a freshly sharpened knife singing through a bunch of chives.

Perhaps the most valuable lesson to learn from this is that sharpening is less an act of maintenance than an act of modification. We’re shaping our knives whether we intend to or not. In this sense, Ho was just being forthright – instead of allowing time and repeated sharpening to form his knife, he did so all at once, expressing his desire with a belt sander.

Knife sharpening, then, is a quiet, entirely private way of actively participating in the creation of the world we inhabit. A knife with good kireaji will both react and reply when you pass it over a whetstone. Such knives are made to be sharpened, to be modified by their users. There’s a sense in which they come to us unfinished, because we have not yet changed them – and they invite us to change our world in ways that only we will really know.