On composites, crayfish, and reinforced concrete's tentative alkalinity.

For most of a red swamp crayfish’s life, cambarincola barbarae are a welcome sight. Barbarae - whitish, leech-like worms, each a couple of millimeters long - eat the swamp scum off the crayfish’s shells and gills, and in most cases improve the crayfish’s health and life expectancy. Together, barbarae and crayfish form a mutualistic symbiotic relationship. Both species benefit from their cohabitation, and barbarae have evolved to the point where their entire life cycle, from egg to adult, occurs while attached to a crayfish.

But their symbiosis is contextual - a tentative truce. Young crayfish (who molt their shells more frequently and therefore accumulate less scum) don’t need much cleaning, and will take pains to remove barbarae from their shells. And even when molting has slowed and a crayfish has allowed the symbiosis to flourish, there are limits to barbarae’s loyalty: If there isn’t enough food for them to survive, they’ll turn parasitic, devouring their host’s gills and eventually killing them.

Like symbioses, composite materials can be incredibly productive: two things coming together to create something stronger. But like crayfish and barbarae, their outcomes can also be tragic. Rarely are two materials a perfect match for each other, and as the environment changes their relationship can turn destructive. And when composites turn destructive - as was evident in the reinforced concrete when the Champlain Towers North were inspected back in 2018 - the fallout can be catastrophic.

The history of what we now call composite materials goes back many thousands of years. For modern consumers, the most common composites are fiber-reinforced plastics (the colloquial “carbon fiber” and “fiberglass”), but perhaps the first composites in history were reinforced mud bricks. The Mesopotamians learned to temper their bricks by mixing straw into them at least as early as 2254 BC, increasing their tensile strength and preventing them from cracking as they dried. This method continues around the world today.

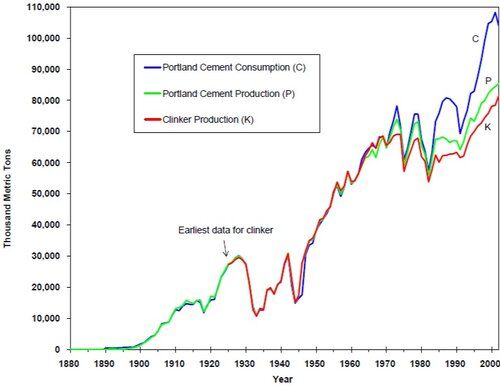

But by far the most commonly used composite material in history is steel-reinforced concrete. Roman concrete usage started as early as 200 BCE, and almost three centuries later Pliny the Elder included a note about what appears to be high quality hydraulic concrete in his Naturalis Historiae. These recipes were subsequently forgotten, and the material largely disappeared between the Pantheon and the mid nineteenth century. Modern concrete involves some legitimate process control: limestone and other materials are heated to around 900° C to create portland cement, which is then pulverized and mixed with water (and aggregate) to create an exothermic reaction resulting in a hard and durable object. The entire process consumes vast amounts of power and produces vast amounts of carbon dioxide, and the industry supporting it today is estimated to be worth about a half a trillion dollars.

But in spite of the fortunes that have been invested in the portland cement process (as well as in a wide range of concrete admixtures, which are used to tune both the wet mixture and the finished product), the true magic of contemporary concrete is the fact that it is so often reinforced with steel - dramatically increasing its tensile strength and making it suitable for a wide range of structural applications. This innovation arose in the mid-nineteenth century, when between 1848 and 1867 it was developed by three successive Frenchmen. In the late 1870s, around the time that the first reinforced concrete building was built in New York City, the American inventor Thaddeus Hyatt noted a critical quality of the material: through some fantastic luck, the coefficients of thermal expansion of steel and concrete are strikingly similar, allowing a composite steel-concrete structure to withstand warm/cool cycles without fracturing. This quality opened up the floodgates, and in the 1880s the pioneering architect-engineer Ernest Ransome built a string of reinforced concrete structures around the San Francisco Bay Area. From there it was history.

More than any other physical technology, it is reinforced concrete that defines the 20th century. Versatile, strong, and (relatively) durable, the material is critical to life and industry as we know it. Reinforced concrete was the material of choice of Albert Kahn, who with Henry Ford defined 20th century industrial architecture; reinforced concrete is a key part of nearly every type of logistical infrastructure, from roads to bridges to container terminals; reinforced concrete makes up the literal launch pads for human space travel. It’s a critical component of power plants, dams, wind turbines, and the vast majority of mid- to late-twentieth century homes and apartment buildings. Its high compressive strength makes it ideally suited for footings and foundations; its high tensile strength lets it cantilever and span great distances easily.

But reinforced concrete is really only 140 years old - the blink of an eye, as far as the infrastructure of old is concerned. The Pantheon was built around 125 CE, by which time the Romans had been experimenting with concrete construction for well over 300 years. When we see the Pantheon, we’re seeing a mature method - a technology with full readiness, being used in an architectural style that’s tuned for its physical properties.

Read the full story

The rest of this post is for paid members only. Sign up now to read the full post — and all of Scope of Work’s other paid posts.

Sign up now