Over the first five years of its existence, this newsletter averaged around six hundred and fifty words per issue, a length that the internet tells me takes five minutes to read. By the end of year six it was hovering around a thousand words per issue, and when I quit my day job it began what appears in retrospect to be a steady and deliberate climb. By the end of 2022 we had crossed two thousand words per issue.

I’m reasonably happy with this trend, but it’s also interesting to play with it from time to time – and my kids’ spring break, which just ended and which I enjoyed being a part of, felt like an appropriate time to experiment with brevity again.

-Spencer Wright

The most clicked link from last week's issue (~9% of opens) was a take-down of all gray interiors. In the Members' Slack, we've been talking about scaling up wiring management, finding the right tool storage system, and how to get an affordable tailored suit.

JOBS.

- The Architect's Newspaper is hiring a staff writer in NYC.

- Anker is hiring a director of industrial design in Shenzhen.

- Form Energy is hiring a lead industrial engineer in Weirton, WV.

- Apple is hiring a product design engineering manager in Cupertino, CA.

- Universal Hydrogen is hiring a director of hydrogen safety in LA.

- More jobs on Scope of Work's job board; you can promote the role you're hiring for here.

PLANNING & STRATEGY.

Sogo shosha, or general trading companies, are a type of large and highly diversified Japanese corporation. Sogo shosha are often wholly or partially owned by a larger company, helping to coordinate production and logistics between the parent company’s different business units. The Mitsubishi, Mitsui, and Sumimoto groups all have their own sogo shosha, each of which is partially owned (roughly 5%) by Berkshire Hathaway.

MAKING & MANUFACTURING.

Hand scraping is the process of using a hardened steel tool – something that looks like an elongated chisel, like this – to precisely remove very fine shavings from a metal part. Hand scraping is an old process, and is still often performed on the ways (note: “ways” is a technical term that refers to the sliding surfaces of a linear bearing) of high end machine tools.

Most machine tool ways start as iron castings, which are cut or ground to a “rough” shape – a process that actually reaches very tight tolerances but can also introduce distortion due to heat or clamping pressure. But there’s another problem with machined and ground surfaces, which is that they can be too smooth, leading them to stick to each other (see wringing) and leaving nowhere for oil to collect. On the other hand, a nicely hand-scraped surface might, as this analysis shows, have a surface texture that’s around 1.5 μm tall, with between one and two high points per square centimeter. When two hand scraped parts slide against each other, only the high points touch; the low points can retain oil, which improves longevity, prevents galling, etc. And hand scraped surfaces can be *dead* flat too, making for the most precise machine tools.

Hand scraping is methodical, rhythmic, and very time consuming; this old NYC CNC video gives a good overview of the process, and this Okuma blog post explains some of the benefits.

MAINTENANCE, REPAIR & OPERATIONS.

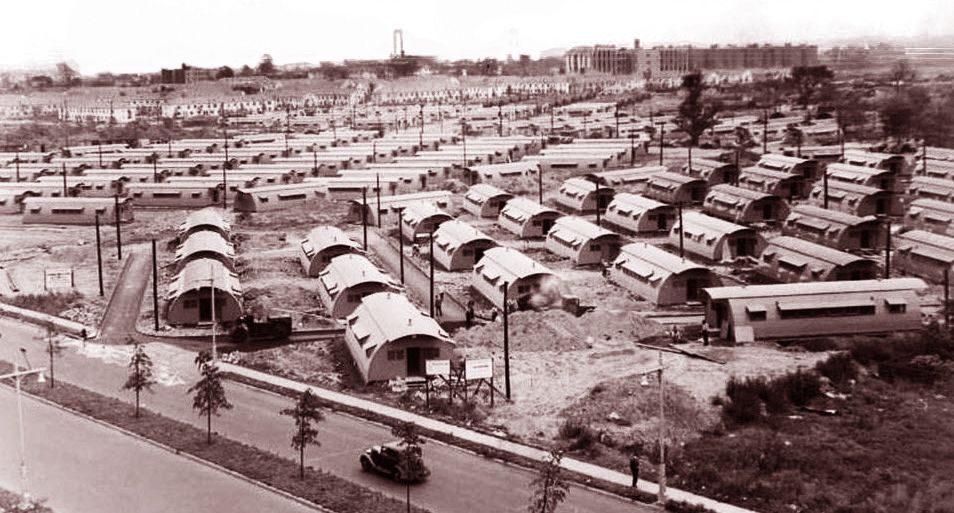

I love Quonset huts. Designed in the 1940s for the US military, they were made in the hundreds of thousands and shipped all over the world for use as barracks, warehouses, and basically anything else. Surplus Quonset huts were sold to the public, and after the war many military Quonset huts were repurposed; you can also buy new Quonset hut kits for the low five figures today.

DISTRIBUTION & LOGISTICS.

When a traditional boat – a canoe, a schooner, a container ship – floats in the water, a large portion of it is under the water line and is said to displace a certain volume of water. The weight of the water that it displaces is called its displacement weight, and it is said to have a displacement hull. This is as opposed to planing hulls and hydrofoils, which lift out of the water when they reach cruising speed. Modern racing yachts like the America’s Cup 75 class have foiling hulls, as do racing dinghies like the Moths seen in this video.

When a displacement hull moves through the water, its bow and stern create waves, which combine to form the boat’s wake. The wake produces drag, and the amount of wave-making drag ends up being a function of the hull’s speed through the water in relation to its length along the water line. In practical terms (n.b., modern naval architects get way deeper here) this means that the longer a displacement hull is, the higher its top speed will be. In traditional boat design, the rule of thumb is that displacement hulls can’t go much faster (in knots) than 2.5x the square root of their length in meters, or 1.34x the square root of their length in feet.

INSPECTION, TESTING & ANALYSIS.

This National Bureau of Economic Research paper on the price of nails since 1695 is long, detailed, and a pretty decent read. I was impressed to learn that pre-industrial hand forged nails took only a minute for a blacksmith to produce (a rate that this random YouTuber doesn’t quite match), though I suppose it’s even more impressive that today, you can buy a nail making machine for under $20k on Alibaba. Tangentially related: This video of nails being aligned with magnets so that they can be boxed up efficiently.

SCOPE CREEP.

My kids’ favorite video right now is a cute stop motion Lego story which was also documented in this nice making-of timelapse.

Thanks as always to Scope of Work’s Members and Supporters for making this newsletter possible. Thanks also to Michael for sending links.

Love, Spencer.

p.s. - We care about inclusivity. Here’s what we’re doing about it.